Page 380 -

P. 380

12.38 CHAPTER TWELVE

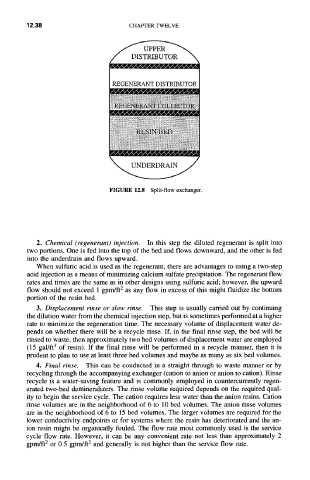

FIGURE 12.8 Split-flow exchanger.

2. Chemical (regenerant) injection. In this step the diluted regenerant is split into

two portions. One is fed into the top of the bed and flows downward, and the other is fed

into the underdrain and flows upward.

When sulfuric acid is used as the regenerant, there are advantages to using a two-step

acid injection as a means of minimizing calcium sulfate precipitation. The regenerant flow

rates and times are the same as in other designs using sulfuric acid; however, the upward

flow should not exceed 1 gpm/ft 2 as any flow in excess of this might fluidize the bottom

portion of the resin bed.

3. Displacement rinse or slow rinse. This step is usually carried out by continuing

the dilution water from the chemical injection step, but is sometimes performed at a higher

rate to minimize the regeneration time. The necessary volume of displacement water de-

pends on whether there will be a recycle rinse. If, in the final rinse step, the bed will be

rinsed to waste, then approximately two bed volumes of displacement water are employed

(15 gal/ft 3 of resin). If the final rinse will be performed in a recycle manner, then it is

prudent to plan to use at least three bed volumes and maybe as many as six bed volumes.

4. Final rinse. This can be conducted in a straight through to waste manner or by

recycling through the accompanying exchanger (cation to anion or anion to cation). Rinse

recycle is a water-saving feature and is commonly employed in countercurrently regen-

erated two-bed demineralizers. The rinse volume required depends on the required qual-

ity to begin the service cycle. The cation requires less water than the anion resins. Cation

rinse volumes are in the neighborhood of 6 to 10 bed volumes. The anion rinse volumes

are in the neighborhood of 6 to 15 bed volumes. The larger volumes are required for the

lower conductivity endpoints or for systems where the resin has deteriorated and the an-

ion resin might be organically fouled. The flow rate most commonly used is the service

cycle flow rate. However, it can be any convenient rate not less than approximately 2

gpm/ft 2 or 0.5 gpm/ft 2 and generally is not higher than the service flow rate.