Page 381 -

P. 381

ION EXCHANGE APPLICATIONS IN WATER TREATMENT 12.39

Countercurrent Regeneration (CCR) Exchanges

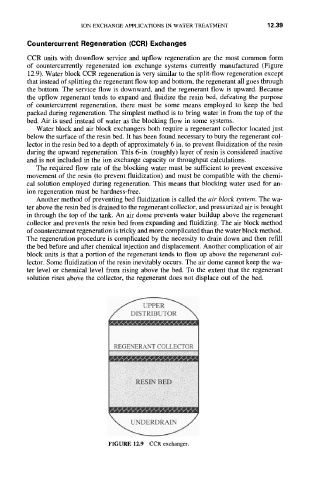

CCR units with downflow service and upflow regeneration are the most common form

of countercurrently regenerated ion exchange systems currently manufactured (Figure

12.9). Water block CCR regeneration is very similar to the split-flow regeneration except

that instead of splitting the regenerant flow top and bottom, the regenerant all goes through

the bottom. The service flow is downward, and the regenerant flow is upward. Because

the upflow regenerant tends to expand and fluidize the resin bed, defeating the purpose

of countercurrent regeneration, there must be some means employed to keep the bed

packed during regeneration. The simplest method is to bring water in from the top of the

bed. Air is used instead of water as the blocking flow in some systems.

Water block and air block exchangers both require a regenerant collector located just

below the surface of the resin bed. It has been found necessary to bury the regenerant col-

lector in the resin bed to a depth of approximately 6 in. to prevent fluidization of the resin

during the upward regeneration. This 6-in. (roughly) layer of resin is considered inactive

and is not included in the ion exchange capacity or throughput calculations.

The required flow rate of the blocking water must be sufficient to prevent excessive

movement of the resin (to prevent fluidization) and must be compatible with the chemi-

cal solution employed during regeneration. This means that blocking water used for an-

ion regeneration must be hardness-free.

Another method of preventing bed fluidization is called the air block system. The wa-

ter above the resin bed is drained to the regenerant collector, and pressurized air is brought

in through the top of the tank. An air dome prevents water buildup above the regenerant

collector and prevents the resin bed from expanding and fluidizing. The air block method

of countercurrent regeneration is tricky and more complicated than the water block method.

The regeneration procedure is complicated by the necessity to drain down and then refill

the bed before and after chemical injection and displacement. Another complication of air

block units is that a portion of the regenerant tends to flow up above the regenerant col-

lector. Some fluidization of the resin inevitably occurs. The air dome cannot keep the wa-

ter level or chemical level from rising above the bed. To the extent that the regenerant

solution rises above the collector, the regenerant does not displace out of the bed.

FIGURE 12.9 CCR exchanger.