Page 433 -

P. 433

13.30 CHAPTER THIRTEEN

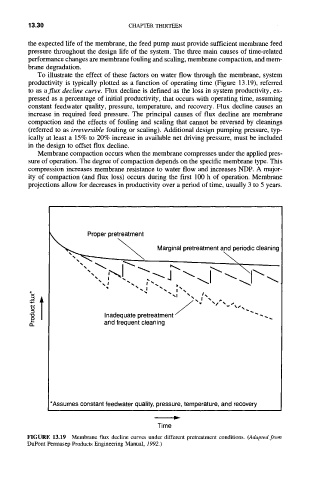

the expected life of the membrane, the feed pump must provide sufficient membrane feed

pressure throughout the design life of the system. The three main causes of time-related

performance changes are membrane fouling and scaling, membrane compaction, and mem-

brane degradation.

To illustrate the effect of these factors on water flow through the membrane, system

productivity is typically plotted as a function of operating time (Figure 13.19), referred

to as aflux decline curve. Flux decline is defined as the loss in system productivity, ex-

pressed as a percentage of initial productivity, that occurs with operating time, assuming

constant feedwater quality, pressure, temperature, and recovery. Flux decline causes an

increase in required feed pressure. The principal causes of flux decline are membrane

compaction and the effects of fouling and scaling that cannot be reversed by cleanings

(referred to as irreversible fouling or scaling). Additional design pumping pressure, typ-

ically at least a 15% to 20% increase in available net driving pressure, must be included

in the design to offset flux decline.

Membrane compaction occurs when the membrane compresses under the applied pres-

sure of operation. The degree of compaction depends on the specific membrane type. This

compression increases membrane resistance to water flow and increases NDP. A major-

ity of compaction (and flux loss) occurs during the first 100 h of operation. Membrane

projections allow for decreases in productivity over a period of time, usually 3 to 5 years.

~ ~ Marginal pretreatment and periodic cleaning

\

...., -..... ;-.

,

"x

%1 %% /%

Inadequate pretreatment / " %'~ " -- ..

and frequent cleaning

¢1

*Assumes constant feedwater quality, pressure, temperature, and recovery

Time

FIGURE 13.19 Membrane flux decline curves under different pretreatment conditions. (Adapted from

DuPont Permasep Products Engineering Manual, 1992.)