Page 465 -

P. 465

ACTIVATED CARBON PROCESSES '14.'13

hausted. Breakthrough curves are important to the designer because they define the rela-

tionship between the physical and chemical parameters of the carbon system (e.g., flow

rate, bed size, carbon exhaustion rate), the determination of the number of beds or columns,

their arrangement (either series or parallel), and treatment plant effluent requirements.

EBCT. EBCT is calculated as the volume of the empty bed (occupied by the GAC)

divided by the volumetric flow rate of water through the carbon. Alternatively, EBCT can

be defined as the depth of GAC divided by the linear velocity of water flowing through

the carbon bed. Note that EBCT is a false-residence time.

EBCT is used instead of detention time because of the ease of calculation. An actual

detention time would have to account for the porosity of the bed, a variable that changes

with carbon size and type. EBCT can be varied by changing the bed depth at constant

flow or by changing flow with constant bed depth. Together, the design EBCT and the

design flow rate define the amount of carbon to be contained in the adsorption units.

Longer EBCTs can delay breakthrough (to a point) and improve carbon usage rate;

shorter EBCTs can expedite breakthrough. Thus the time of GAC operation between re-

placement or regeneration depends on the EBCT. For most water treatment applications,

EBCTs range between 5 and 25 min. In addition, a factor having a greater influence on

operating costs than EBCT is volume throughput, which is the number of bed volumes

of water processed before the breakthrough concentration is reached.

Adsorber Volume and Bed Depth. After the EBCT has been determined, carbon vol-

ume and bed depth can be selected. The adsorber design volume depends on bed volume

and the amount of freeboard (excess vessel capacity beyond design operating levels). Free-

board can range up to about 50% for fixed and expanded bed systems. If bed expansion

is unnecessary, a freeboard of 20% to 30% may be adequate to allow for proper bed ex-

pansion during backwashing.

No freeboard is needed for upflow pulsed beds. An economic evaluation is usually

made of capital and operating costs to compare carbon columns of various depths.

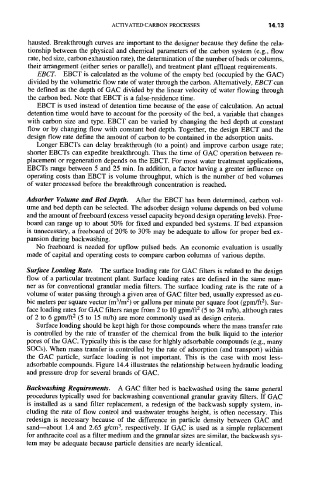

Surface Loading Rate. The surface loading rate for GAC filters is related to the design

flow of a particular treatment plant. Surface loading rates are defined in the same man-

ner as for conventional granular media filters. The surface loading rate is the rate of a

volume of water passing through a given area of GAC filter bed, usually expressed as cu-

bic meters per square vector (m3/m 2) or gallons per minute per square foot (gpm/ft2). Sur-

face loading rates for GAC filters range from 2 to 10 gpm/ft 2 (5 to 24 m/h), although rates

of 2 to 6 gpm/ft 2 (5 to 15 m/h) are more commonly used as design criteria.

Surface loading should be kept high for those compounds where the mass transfer rate

is controlled by the rate of transfer of the chemical from the bulk liquid to the interior

pores of the GAC. Typically this is the case for highly adsorbable compounds (e.g., many

SOCs). When mass transfer is controlled by the rate of adsorption (and transport) within

the GAC particle, surface loading is not important. This is the case with most less-

adsorbable compounds, Figure 14.4 illustrates the relationship between hydraulic loading

and pressure drop for several brands of GAC.

Backwashing Requirements. A GAC filter bed is backwashed using the same general

procedures typically used for backwashing conventional granular gravity filters. If GAC

is installed as a sand filter replacement, a redesign of the backwash supply system, in-

cluding the rate of flow control and washwater troughs height, is often necessary. This

redesign is necessary because of the difference in particle density between GAC and

sand---about 1.4 and 2.65 g/cm 3, respectively. If GAC is used as a simple replacement

for anthracite coal as a filter medium and the granular sizes are similar, the backwash sys-

tem may be adequate because particle densities are nearly identical.