Page 101 - 3D Fibre Reinforced Polymer Composites

P. 101

90 30 Fibre Reinforced Polymer Composites

lenticular cross-section, and macroscopically homogeneous in-plane extension and

shear and transverse shear loadings are considered.

A unified prediction method ranging from micro model (named as fibre bundle

model) to macro model (named as weaving structure model) was developed by Fujita et

ai. (1995). In the fibre bundle model, one fibre bundle was modelled with beam

elements. Resin elements are set up to connect fibre beam elements. As the rule of

mixture is used to calculate the material constants of the fibre element, this model can

be used to study micro phenomena within fibre bundle. For the weaving structure

model, the weaving structure of textile composites is modelled by connecting the beam

elements. Resin existing between crossing fibre bundles is also modelled by resin

elements. The section of the fibre bundle is approximately in a rectangular shape,

whose area is assumed to be equal to that of the fibre bundle measured. This model was

only used to simulate the mechanical behaviours of 2D textile composites, and

dependence of the mechanical properties on the textile structural parameters was

however not investigated.

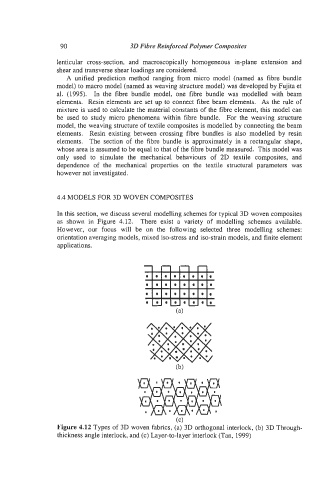

4.4 MODELS FOR 3D WOVEN COMPOSITES

In this section, we discuss several modelling schemes for typical 3D woven composites

as shown in Figure 4.12. There exist a variety of modelling schemes available.

However, our focus will be on the following selected three modelling schemes:

orientation averaging models, mixed iso-stress and iso-strain models, and finite element

applications.

(c)

Figure 4.12 Types of 3D woven fabrics, (a) 3D orthogonal interlock, (b) 3D Through-

thickness angle interlock, and (c) Layer-to-layer interlock (Tan, 1999)