Page 152 - 3D Fibre Reinforced Polymer Composites

P. 152

Braided Composite Materials 141

Table 6.4. These results again illustrate the improvement in longitudinal mechanical

performance that can be obtained by the presence of axial fibres in the 2-step braided

composite. In spite of the fact that the 4-step braided specimen had a significantly lower

braid angle then the 2-step, the effect of lower braid angle was not enough to offset the

very high proportion of axial fibres contained in the 2-step specimen. It was concluded

that the relatively low value of the compressive strength for the 4-step braided

composite was due to the waviness in the braiding yarns that can result from the 4-step

process. It is important to note that the shear strength of the 4-step specimen is higher

than that of the 2-step. This is thought to be an outcome of the higher amount of angled

braiding yarns in the 4-step specimen improving the transverse properties of the

composite. A similar improvement in longitudinal mechanical properties of 2-step

braided composites over 4-step has been observed by Wenning et al. (1993) and Li et al.

(1988).

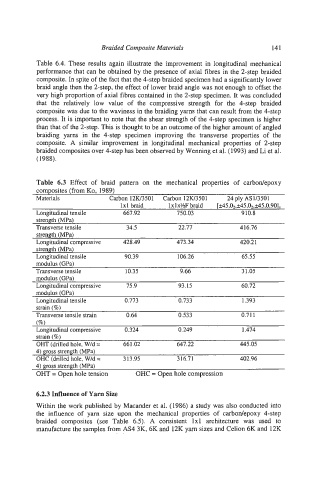

Table 6.3 Effect of braid pattern on the mechanical properties of carbodepoxy

composites (from KO, 1989)

Materials Carbon 12W3501 Carbon 12IU3501 24 ply AS113501

1 x 1 braid lxlxYiF braid [*45,02,*45,02,*45,0,90),

Longitudinal tensile 667.92 750.03 910.8

strength (MPa)

Transverse tensile 34.5 22.77 416.76

strength (MPa)

Longitudinal compressive 428.49 473.34 420.21

strength (MPa)

Longitudinal tensile 90.39 106.26 65.55

modulus (GPa)

Transverse tensile 10.35 9.66 3 1 .OS

modulus (GPa)

Longitudinal compressive 75.9 93.15 60.72

modulus (GPa)

Longitudinal tensile 0.773 0.733 1.393

straii (%)

Transverse tensile strain 0.64 0.533 0.71 1

(%)

Longitudinal compressive 0.324 0.249 1.474

strain (%)

OHT (drilled hole, W/d = 661.02 647.22 445.05

4) gross strength (MPa)

OHC (drilled hole, W/d = 313.95 316.71 402.96

4) gross strength (MPa)

OHT = Open hole tension OHC = Open hole compression

6.2.3 Influence of Yarn Size

Within the work published by Macander et al. (1986) a study was also conducted into

the influence of yarn size upon the mechanical properties of carbodepoxy 4-step

braided composites (see Table 6.5). A consistent 1x1 architecture was used to

manufacture the samples from AS4 3K, 6K and 12K yam sizes and Celion 6K and 12K