Page 149 - 3D Fibre Reinforced Polymer Composites

P. 149

138 30 Fibre Reinforced Polymer Composites

In spite of the limited data available in the published literature there are some general

conclusions that can be drawn on the mechanical properties of 3D braided composites

and these are summarised in the following sections.

6.2 IN-PLANE MECHANICAL PROPERTIES

Two comprehensive studies of the in-plane mechanical properties of 3D braided

composites were carried out in the mid-1980's by Macander, Crane & Camponeschi

(1986) and Gause & Alper (1987). In these two publications the effect of changes to a

number of braiding variables on the tensile, compressive and other in-plane properties

were investigated. Data was generated on preforms constructed by the 4-step, or row-

and-column, braiding process.

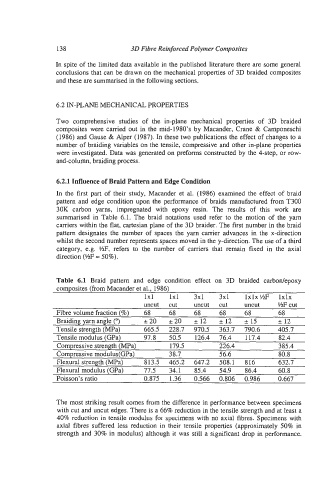

6.2.1 Influence of Braid Pattern and Edge Condition

In the first part of their study, Macander et al. (1986) examined the effect of braid

pattern and edge condition upon the performance of braids manufactured from T300

30K carbon yarns, impregnated with epoxy resin. The results of this work are

summarised in Table 6.1. The braid notations used refer to the motion of the yarn

carriers within the flat, Cartesian plane of the 3D braider. The first number in the braid

pattern designates the number of spaces the yam carrier advances in the x-direction

whilst the second number represents spaces moved in the y-direction. The use of a third

category, e.g. YiF, refers to the number of carriers that remain fixed in the axial

direction (%F = 50%).

Table 6.1 Braid pattern and edge condition effect on 3D braided carbon/epoxy

composites (from Macander et al., 1986)

1x1 1x1 3x1 3x1 lxlx4iF lxlx

uncut cut uncut cut uncut %F cut

Fibre volume fraction (%) 68 68 68 68 68 68

Braiding yarn angle (") 520 *20 f 12 -c 12 +15 * 12

TensiIe strength (MPa) 665.5 228.7 970.5 363.7 790.6 405.7

Tensile modulus (GPa) 97.8 50.5 126.4 76.4 117.4 82.4

Compressive strength (MPa) 179.5 226.4 3 85.4

Compressive modulus(GPa) 38.7 56.6 80.8

Flexural strength (MPa) 813.5 465.2 647.2 508.1 816 632.7

Flexural modulus (GPa) 77.5 34.1 85.4 54.9 86.4 60.8

Poisson's ratio 0.875 1.36 0.566 0.806 0.986 0.667

The most striking result comes from the difference in performance between specimens

with cut and uncut edges. There is a 66% reduction in the tensile strength and at least a

40% reduction in tensile modulus for specimens with no axial fibres. Specimens with

axial fibres suffered less reduction in their tensile properties (approximately 50% in

strength and 30% in modulus) although it was still a significant drop in performance.