Page 176 - 3D Fibre Reinforced Polymer Composites

P. 176

Stitched Composites 165

fibres as it pierces the preform. Sewing prepreg tape can be more difficult because the

inherent tackiness of the uncured resin matrix impedes the needle action. The materials

most often used as the reinforcing threads for stitching are carbon, glass and Kevlar

yarns, although it is possible to sew with other types of fibrous materials including

Spectra@ and high strength thermoplastics. The yarns can be sewn into the preform in a

variety of patterns, with the most common types being the lock stitch, modified lock

stitch and chain stitch. These three stitch types are shown in Figure 8.2 (Morales,

1990). The standard lock and chain stitches are used occasionally, but the most popular

stitch style is the modified lock stitch in which the loops crossing the needle and bobbin

threads are formed at one surface of the composite to minimise in-plane fibre distortions

inside the material.

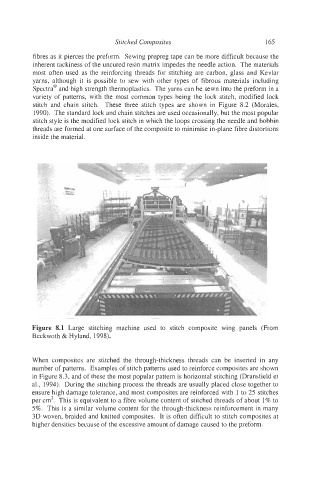

Figure 8.1 Large stitching machine used to stitch composite wing panels (From

Beckwoth & Hyland, 1998).

When composites are stitched the through-thickness threads can be inserted in any

number of patterns. Examples of stitch patterns used to reinforce composites are shown

in Figure 8.3, and of these the most popular pattern is horizontal stitching (Dransfield et

al., 1994). During the stitching process the threads are usually placed close together to

ensure high damage tolerance, and most composites are reinforced with 1 to 25 stitches

per cm2. This is equivalent to a fibre volume content of stitched threads of about 1% to

5%. This is a similar volume content for the through-thickness reinforcement in many

3D woven, braided and knitted composites. It is often difficult to stitch composites at

higher densities because of the excessive amount of damage caused to the preform.