Page 180 - 3D Fibre Reinforced Polymer Composites

P. 180

Stitched Composites 169

(f)

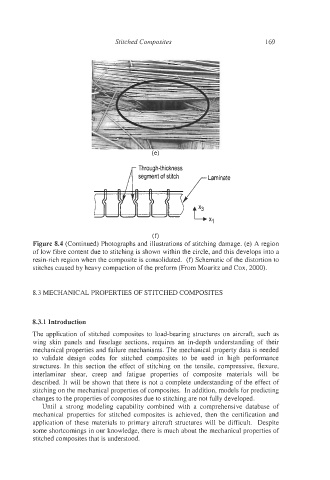

Figure 8.4 (Continued) Photographs and illustrations of stitching damage. (e) A region

of low fibre content due to stitching is shown within the circle, and this develops into a

resin-rich region when the composite is consolidated. (f) Schematic of the distortion to

stitches caused by heavy compaction of the preform (From Mouritz and Cox, 2000).

8.3 MECHANICAL PROPERTIES OF STITCHED COMPOSITES

8.3.1 Introduction

The application of stitched composites to load-bearing structures on aircraft, such as

wing skin panels and fuselage sections, requires an in-depth understanding of their

mechanical properties and failure mechanisms. The mechanical property data is needed

to validate design codes for stitched composites to be used in high performance

structures. In this section the effect of stitching on the tensile, compressive, flexure,

interlaminar shear, creep and fatigue properties of composite materials will be

described. It will be shown that there is not a complete understanding of the effect of

stitching on the mechanical properties of composites. In addition, models for predicting

changes to the properties of composites due to stitching are not fully developed.

Until a strong modeling capability combined with a comprehensive database of

mechanical properties for stitched composites is achieved, then the certification and

application of these materials to primary aircraft structures will be difficult. Despite

some shortcomings in our knowledge, there is much about the mechanical properties of

stitched composites that is understood.