Page 198 - 3D Fibre Reinforced Polymer Composites

P. 198

Stitched Composites 187

to the toughness of the equivalent unstitched laminate (G,,). The figure shows a general

increase to the interlaminar fracture toughness with increasing stitch density. A few

outlying data points show that the delamination resistance can be improved by over 30

times by stitching with exceptionally thick, strong threads. For most composites,

however, stitching increases the delamination resistance by a factor of up to 10-15. This

compares favourably with other types of 3D composites that have interlaminar fracture

toughness properties that are up to 20 times higher than the equivalent 2D laminate.

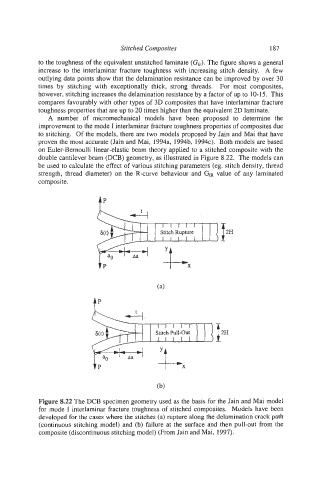

A number of micromechanical models have been proposed to determine the

improvement to the mode I interlaminar fracture toughness properties of composites due

to stitching. Of the models, there are two models proposed by Jain and Mai that have

proven the most accurate (Jain and Mai, 1994a, 1994b, 1994~). Both models are based

on Euler-Bernoulli linear-elastic beam theory applied to a stitched composite with the

double cantilever beam (DCB) geometry, as illustrated in Figure 8.22. The models can

be used to caIculate the effect of various stitching parameters (eg. stitch density, thread

strength, thread diameter) on the R-curve behaviour and GIR value of any laminated

composite.

tp

- Stitch Rupture I

I

I

I

I

I I I I I

(a>

I I I I I

Stitch Pull-Out

IIIII

Figure 8.22 The DCB specimen geometry used as the basis for the Jain and Mai model

for mode I interlaminar fracture toughness of stitched composites. Models have been

developed for the cases where the stitches (a) rupture along the delamination crack path

(continuous stitching model) and (b) failure at the surface and then pull-out from the

composite (discontinuous stitching model) (From Jain and Mai, 1997).