Page 194 - 3D Fibre Reinforced Polymer Composites

P. 194

Stitched Composites 183

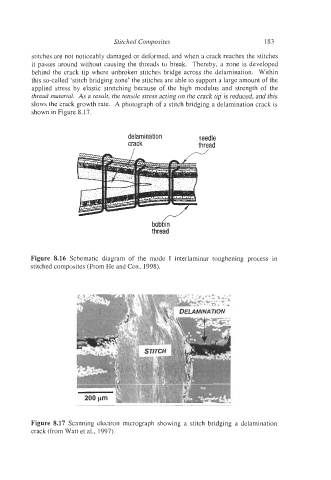

stitches are not noticeably damaged or deformed, and when a crack reaches the stitches

it passes around without causing the threads to break. Thereby, a zone is developed

behind the crack tip where unbroken stitches bridge across the delamination. Within

this so-called ‘stitch bridging zone’ the stitches are able to support a large amount of the

applied stress by elastic stretching because of the high modulus and strength of the

thread material. As a result, the tensile stress acting on the crack tip is reduced, and this

slows the crack growth rate. A photograph of a stitch bridging a delamination crack is

shown in Figure 8.17.

delamination needle

crack thread

bobbin

thread

Figure 8.16 Schematic diagram of the mode I interlaminar toughening process in

stitched composites (From He and Cox, 1998).

Figure 8.17 Scanning electron micrograph showing a stitch bridging a delamination

crack (from Watt et al., 1997).