Page 88 - 3D Fibre Reinforced Polymer Composites

P. 88

Micromechanics Models for Mechanical Properties 77

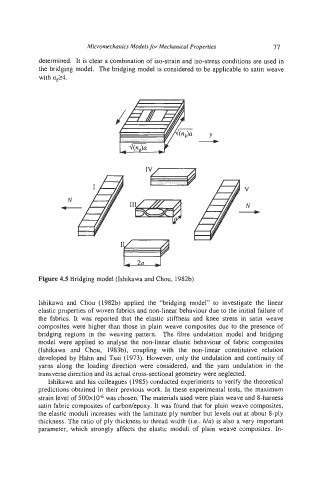

determined. It is clear a combination of iso-strain and iso-stress conditions are used in

the bridging model. The bridging model is considered to be applicable to satin weave

with n,24.

- -

V

N

N

Figure 4.5 Bridging model (Ishikawa and Chou, 1982b)

Ishikawa and Chou (1982b) applied the “bridging model” to investigate the linear

elastic properties of woven fabrics and non-linear behaviour due to the initial failure of

the fabrics. It was reported that the elastic stiffness and knee stress in satin weave

composites were higher than those in plain weave composites due to the presence of

bridging regions in the weaving pattern. The fibre undulation model and bridging

model were applied to analyse the non-linear elastic behaviour of fabric composites

(Ishikawa and Chou, 1983b), coupling with the non-linear constitutive relation

developed by Hahn and Tsai (1973). However, only the undulation and continuity of

yams along the loading direction were considered, and the yarn undulation in the

transverse direction and its actual cross-sectional geometry were neglected.

Ishikawa and his colleagues (1 985) conducted experiments to verify the theoretical

predictions obtained in their previous work. In these experimental tests, the maximum

strain level of ~OOXIO-~ was chosen. The materials used were plain weave and 8-harness

satin fabric composites of carbodepoxy. It was found that for plain weave composites,

the elastic moduii increases with the laminate ply number but levels out at about 8-ply

thickness. The ratio of ply thickness to thread width (i.e., Mu) is also a very important

parameter, which strongly affects the elastic moduli of plain weave composites. In-