Page 87 - 3D Fibre Reinforced Polymer Composites

P. 87

76 30 Fibre Reinforced Polymer Composites

-

2a

d.. =(l-A)dl; +- 2 u= (4.34)

Jdl;”(x)dx

Y

n8a n8a Uo

where ai., b,]: and dli are the stretching, stretching-bending coupling and bending

compliance matrices of a two-ply cross-ply asymmetrical laminate, Le., the straight

portion. a:, bly and d;” are those for the undulated portion. This model is an

extension of the series model and is applicable to weaves with low ng values, i.e., n,=2.

Both the mosaic model and fibre undulation model are useful for understanding the

basic aspects of the mechanical properties for woven fabrics. For example, it was found

that the relationship between the in-plane stiffness CI1 and lln, by applying the well-

known “mosaic model” and “fibre undulation model” shows that the reduction in CI1

due to fibre undulation is most severe in plain woven (n,=2) as compared to cross-ply

laminates (l/nFO, ie., straight yarn).

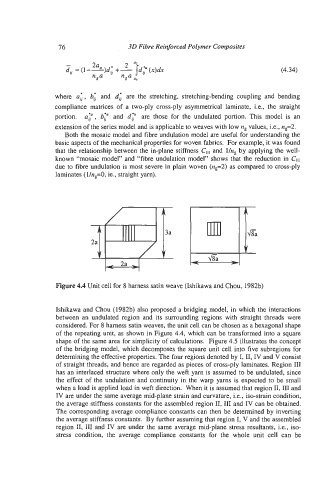

Figure 4.4 Unit cell for 8 harness satin weave (Ishikawa and Chou, 1982b)

Ishikawa and Chou (1982b) also proposed a bridging model, in which the interactions

between an undulated region and its surrounding regions with straight threads were

considered. For 8 harness satin weaves, the unit cell can be chosen as a hexagonal shape

of the repeating unit, as shown in Figure 4.4, which can be transformed into a square

shape of the same area for simplicity of calculations. Figure 4.5 illustrates the concept

of the bridging model, which decomposes the square unit cell into five subregions for

determining the effective properties. The four regions denoted by I, 11, IV and V consist

of straight threads, and hence are regarded as pieces of cross-ply laminates. Region I11

has an interlaced structure where only the weft yarn is assumed to be undulated, since

the effect of the undulation and continuity in the warp yarns is expected to be small

when a load is applied load in weft direction. When it is assumed that region 11, I11 and

IV are under the same average mid-plane strain and curvature, Le., iso-strain condition,

the average stiffness constants for the assembled region 11, I11 and IV can be obtained.

The corresponding average compliance constants can then be determined by inverting

the average stiffness constants. By further assuming that region I, V and the assembled

region 11, I11 and IV are under the same average mid-plane stress resultants, i.e., iso-

stress condition, the average compliance constants for the whole unit cell can be