Page 205 - A Practical Companion to Reservoir Stimulation

P. 205

PRACTICAL COMPANION TO RESERVOIR STIMULATION

tant on continuous-mixed treatments. If the base fluid has not

moved far enough along in the hydration process before the

fluid is crosslinked, the fluid may experience stability prob-

lems.

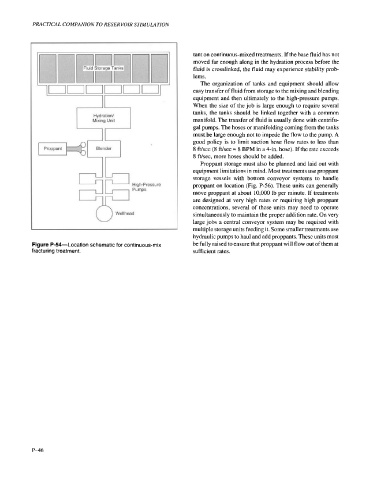

The organization of tanks and equipment should allow

easy transfer of fluid from storage to the mixing and blending

equipment and then ultimately to the high-pressure pumps.

When the size of the job is large enough to require several

tanks, the tanks should be linked together with a common

manifold. The transfer of fluid is usually done with centrifu-

gal pumps. The hoses or manifolding coming from the tanks

must.be large enough not to impede the flow to the pump. A

good policy is to limit suction hose flow rates to less than

8 ft/sec (8 ft/sec = 8 BPM in a 4-in. hose). If the rate exceeds

8 ft/sec, more hoses should be added.

Proppant storage must also be planned and laid out with

equipment limitations in mind. Most treatments use proppant

storage vessels with bottom conveyor systems to handle

proppant on location (Fig. P-56). These units can generally

move proppant at about 10,000 lb per minute. If treatments

are designed at very high rates or requiring high proppant

concentrations, several of these units may need to operate

simultaneously to maintain the proper addition rate. On very

large jobs a central conveyor system may be required with

multiple storage units feeding it. Some smaller treatments use

hydraulic pumps to haul and add proppants. These units must

Figure P-54-Location schematic for continuous-mix be fully raised to ensure that proppant will flow out of them at

fracturing treatment. sufficient rates.

P-46