Page 148 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 148

A Quick Guide to Welding and Weld Inspection

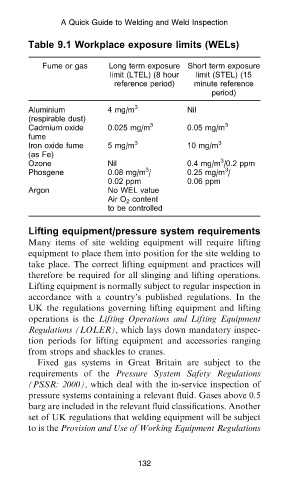

Table 9.1 Workplace exposure limits (WELs)

Fume or gas Long term exposure Short term exposure

limit (LTEL) (8 hour limit (STEL) (15

reference period) minute reference

period)

Aluminium 4 mg/m 3 Nil

(respirable dust)

Cadmium oxide 0.025 mg/m 3 0.05 mg/m 3

fume

Iron oxide fume 5 mg/m 3 10 mg/m 3

(as Fe)

3

Ozone Nil 0.4 mg/m /0.2 ppm

3

3

Phosgene 0.08 mg/m / 0.25 mg/m /

0.02 ppm 0.06 ppm

Argon No WEL value

Air O 2 content

to be controlled

Lifting equipment/pressure system requirements

Many items of site welding equipment will require lifting

equipment to place them into position for the site welding to

take place. The correct lifting equipment and practices will

therefore be required for all slinging and lifting operations.

Lifting equipment is normally subject to regular inspection in

accordance with a country’s published regulations. In the

UK the regulations governing lifting equipment and lifting

operations is the Lifting Operations and Lifting Equipment

Regulations (LOLER), which lays down mandatory inspec-

tion periods for lifting equipment and accessories ranging

from strops and shackles to cranes.

Fixed gas systems in Great Britain are subject to the

requirements of the Pressure System Safety Regulations

(PSSR: 2000), which deal with the in-service inspection of

pressure systems containing a relevant fluid. Gases above 0.5

barg are included in the relevant fluid classifications. Another

set of UK regulations that welding equipment will be subject

to is the Provision and Use of Working Equipment Regulations

132

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200909QG Welding chap9.3d Page 132 of 134