Page 151 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 151

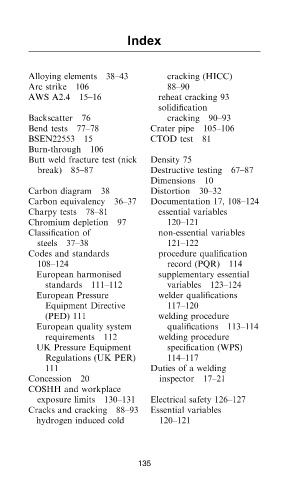

Index

Alloying elements 38–43 cracking (HICC)

Arc strike 106 88–90

AWS A2.4 15–16 reheat cracking 93

solidification

Backscatter 76 cracking 90–93

Bend tests 77–78 Crater pipe 105–106

BSEN22553 15 CTOD test 81

Burn-through 106

Butt weld fracture test (nick Density 75

break) 85–87 Destructive testing 67–87

Dimensions 10

Carbon diagram 38 Distortion 30–32

Carbon equivalency 36–37 Documentation 17, 108–124

Charpy tests 78–81 essential variables

Chromium depletion 97 120–121

Classification of non-essential variables

steels 37–38 121–122

Codes and standards procedure qualification

108–124 record (PQR) 114

European harmonised supplementary essential

standards 111–112 variables 123–124

European Pressure welder qualifications

Equipment Directive 117–120

(PED) 111 welding procedure

European quality system qualifications 113–114

requirements 112 welding procedure

UK Pressure Equipment specification (WPS)

Regulations (UK PER) 114–117

111 Duties of a welding

Concession 20 inspector 17–21

COSHH and workplace

exposure limits 130–131 Electrical safety 126–127

Cracks and cracking 88–93 Essential variables

hydrogen induced cold 120–121

135

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200910QG Welding index.3d Page 135 of 138