Page 152 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 152

A Quick Guide to Welding and Weld Inspection

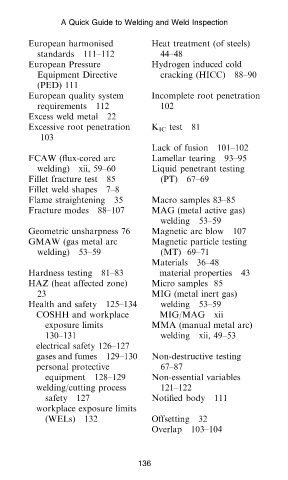

European harmonised Heat treatment (of steels)

standards 111–112 44–48

European Pressure Hydrogen induced cold

Equipment Directive cracking (HICC) 88–90

(PED) 111

European quality system Incomplete root penetration

requirements 112 102

Excess weld metal 22

Excessive root penetration K IC test 81

103

Lack of fusion 101–102

FCAW (flux-cored arc Lamellar tearing 93–95

welding) xii, 59–60 Liquid penetrant testing

Fillet fracture test 85 (PT) 67–69

Fillet weld shapes 7–8

Flame straightening 35 Macro samples 83–85

Fracture modes 88–107 MAG (metal active gas)

welding 53–59

Geometric unsharpness 76 Magnetic arc blow 107

GMAW (gas metal arc Magnetic particle testing

welding) 53–59 (MT) 69–71

Materials 36–48

Hardness testing 81–83 material properties 43

HAZ (heat affected zone) Micro samples 85

23 MIG (metal inert gas)

Health and safety 125–134 welding 53–59

COSHH and workplace MIG/MAG xii

exposure limits MMA (manual metal arc)

130–131 welding xii, 49–53

electrical safety 126–127

gases and fumes 129–130 Non-destructive testing

personal protective 67–87

equipment 128–129 Non-essential variables

welding/cutting process 121–122

safety 127 Notified body 111

workplace exposure limits

(WELs) 132 Offsetting 32

Overlap 103–104

136

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200910QG Welding index.3d Page 136 of 138