Page 154 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 154

A Quick Guide to Welding and Weld Inspection

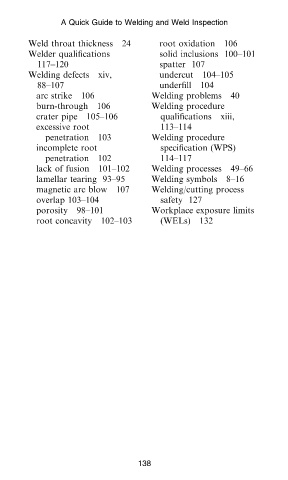

Weld throat thickness 24 root oxidation 106

Welder qualifications solid inclusions 100–101

117–120 spatter 107

Welding defects xiv, undercut 104–105

88–107 underfill 104

arc strike 106 Welding problems 40

burn-through 106 Welding procedure

crater pipe 105–106 qualifications xiii,

excessive root 113–114

penetration 103 Welding procedure

incomplete root specification (WPS)

penetration 102 114–117

lack of fusion 101–102 Welding processes 49–66

lamellar tearing 93–95 Welding symbols 8–16

magnetic arc blow 107 Welding/cutting process

overlap 103–104 safety 127

porosity 98–101 Workplace exposure limits

root concavity 102–103 (WELs) 132

138

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200910QG Welding index.3d Page 138 of 138