Page 68 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 68

Welding Processes

Applications

Common uses of MMA are welding of pipelines, nozzles and

nodes and medium to heavy fabrications. MMA is com-

monly used outdoors owing to the good gas shielding

supplied from the melting flux.

Typical defects

Typical defects include slag inclusions, porosity, undercut,

lack of fusion and profile defects.

Metal inert gas (MIG)/metal active gas (MAG)/gas

metal arc welding (GMAW)

Process description

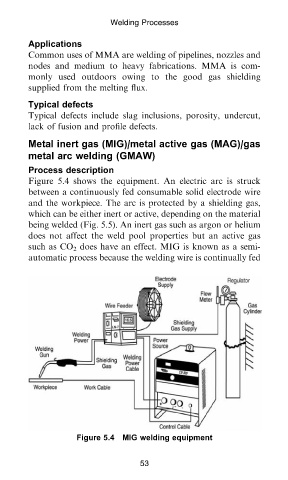

Figure 5.4 shows the equipment. An electric arc is struck

between a continuously fed consumable solid electrode wire

and the workpiece. The arc is protected by a shielding gas,

which can be either inert or active, depending on the material

being welded (Fig. 5.5). An inert gas such as argon or helium

does not affect the weld pool properties but an active gas

such as CO 2 does have an effect. MIG is known as a semi-

automatic process because the welding wire is continually fed

Figure 5.4 MIG welding equipment

53

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200905QG Welding chap5.3d Page 53 of 66