Page 69 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 69

A Quick Guide to Welding and Weld Inspection

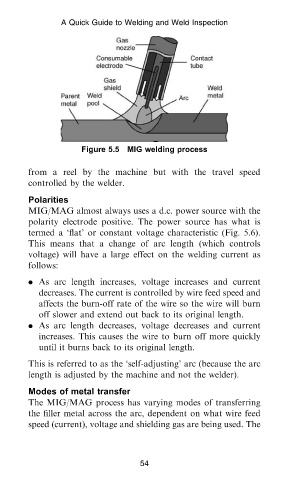

Figure 5.5 MIG welding process

from a reel by the machine but with the travel speed

controlled by the welder.

Polarities

MIG/MAG almost always uses a d.c. power source with the

polarity electrode positive. The power source has what is

termed a ‘flat’ or constant voltage characteristic (Fig. 5.6).

This means that a change of arc length (which controls

voltage) will have a large effect on the welding current as

follows:

. As arc length increases, voltage increases and current

decreases. The current is controlled by wire feed speed and

affects the burn-off rate of the wire so the wire will burn

off slower and extend out back to its original length.

. As arc length decreases, voltage decreases and current

increases. This causes the wire to burn off more quickly

until it burns back to its original length.

This is referred to as the ‘self-adjusting’ arc (because the arc

length is adjusted by the machine and not the welder).

Modes of metal transfer

The MIG/MAG process has varying modes of transferring

the filler metal across the arc, dependent on what wire feed

speed (current), voltage and shielding gas are being used. The

54

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200905QG Welding chap5.3d Page 54 of 66