Page 70 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 70

Welding Processes

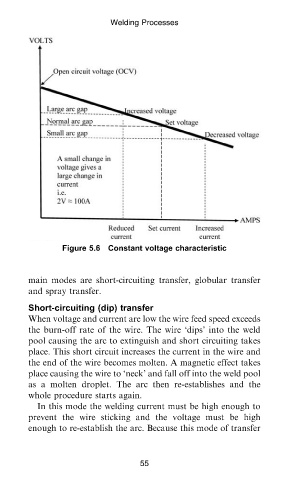

Figure 5.6 Constant voltage characteristic

main modes are short-circuiting transfer, globular transfer

and spray transfer.

Short-circuiting (dip) transfer

When voltage and current are low the wire feed speed exceeds

the burn-off rate of the wire. The wire ‘dips’ into the weld

pool causing the arc to extinguish and short circuiting takes

place. This short circuit increases the current in the wire and

the end of the wire becomes molten. A magnetic effect takes

place causing the wire to ‘neck’ and fall off into the weld pool

as a molten droplet. The arc then re-establishes and the

whole procedure starts again.

In this mode the welding current must be high enough to

prevent the wire sticking and the voltage must be high

enough to re-establish the arc. Because this mode of transfer

55

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200905QG Welding chap5.3d Page 55 of 66