Page 90 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 90

Non-destructive and Destructive Testing

1. Density is a measure of how much light passes through

the film. The higher the density number, the darker the

film. Normal acceptance levels are densities of between

1.8 minimum to 4.0 maximum for X-ray and 2.0 to 4.0

for gamma, but it varies between standards. The density

measurement is normally taken along the area of interest

(i.e. the weld length) using a piece of equipment called a

densitometer.

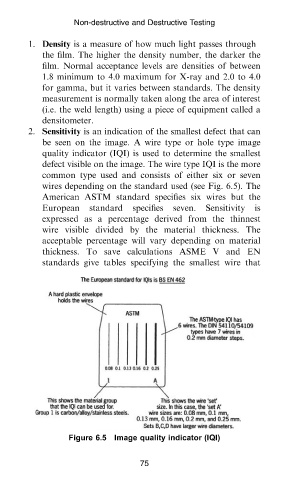

2. Sensitivity is an indication of the smallest defect that can

be seen on the image. A wire type or hole type image

quality indicator (IQI) is used to determine the smallest

defect visible on the image. The wire type IQI is the more

common type used and consists of either six or seven

wires depending on the standard used (see Fig. 6.5). The

American ASTM standard specifies six wires but the

European standard specifies seven. Sensitivity is

expressed as a percentage derived from the thinnest

wire visible divided by the material thickness. The

acceptable percentage will vary depending on material

thickness. To save calculations ASME V and EN

standards give tables specifying the smallest wire that

Figure 6.5 Image quality indicator (IQI)

75

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200906QG Welding chap6.3d Page 75 of 87