Page 94 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 94

Non-destructive and Destructive Testing

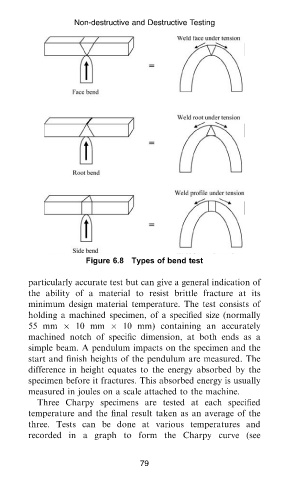

Figure 6.8 Types of bend test

particularly accurate test but can give a general indication of

the ability of a material to resist brittle fracture at its

minimum design material temperature. The test consists of

holding a machined specimen, of a specified size (normally

55 mm 10 mm 10 mm) containing an accurately

machined notch of specific dimension, at both ends as a

simple beam. A pendulum impacts on the specimen and the

start and finish heights of the pendulum are measured. The

difference in height equates to the energy absorbed by the

specimen before it fractures. This absorbed energy is usually

measured in joules on a scale attached to the machine.

Three Charpy specimens are tested at each specified

temperature and the final result taken as an average of the

three. Tests can be done at various temperatures and

recorded in a graph to form the Charpy curve (see

79

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200906QG Welding chap6.3d Page 79 of 87