Page 98 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 98

A Quick Guide to Welding and Weld Inspection

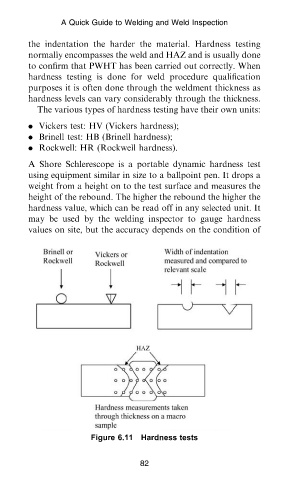

the indentation the harder the material. Hardness testing

normally encompasses the weld and HAZ and is usually done

to confirm that PWHT has been carried out correctly. When

hardness testing is done for weld procedure qualification

purposes it is often done through the weldment thickness as

hardness levels can vary considerably through the thickness.

The various types of hardness testing have their own units:

. Vickers test: HV (Vickers hardness);

. Brinell test: HB (Brinell hardness);

. Rockwell: HR (Rockwell hardness).

A Shore Schlerescope is a portable dynamic hardness test

using equipment similar in size to a ballpoint pen. It drops a

weight from a height on to the test surface and measures the

height of the rebound. The higher the rebound the higher the

hardness value, which can be read off in any selected unit. It

may be used by the welding inspector to gauge hardness

values on site, but the accuracy depends on the condition of

Figure 6.11 Hardness tests

82

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200906QG Welding chap6.3d Page 82 of 87