Page 97 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 97

Non-destructive and Destructive Testing

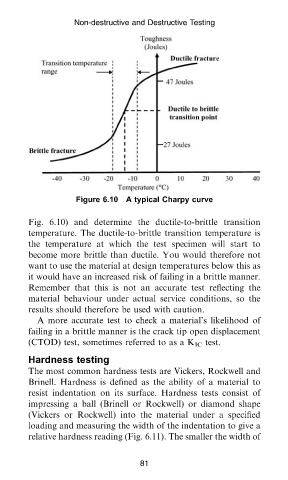

Figure 6.10 A typical Charpy curve

Fig. 6.10) and determine the ductile-to-brittle transition

temperature. The ductile-to-brittle transition temperature is

the temperature at which the test specimen will start to

become more brittle than ductile. You would therefore not

want to use the material at design temperatures below this as

it would have an increased risk of failing in a brittle manner.

Remember that this is not an accurate test reflecting the

material behaviour under actual service conditions, so the

results should therefore be used with caution.

A more accurate test to check a material’s likelihood of

failing in a brittle manner is the crack tip open displacement

(CTOD) test, sometimes referred to as a K IC test.

Hardness testing

The most common hardness tests are Vickers, Rockwell and

Brinell. Hardness is defined as the ability of a material to

resist indentation on its surface. Hardness tests consist of

impressing a ball (Brinell or Rockwell) or diamond shape

(Vickers or Rockwell) into the material under a specified

loading and measuring the width of the indentation to give a

relative hardness reading (Fig. 6.11). The smaller the width of

81

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200906QG Welding chap6.3d Page 81 of 87