Page 376 - Accounting Information Systems

P. 376

C H A P TER 7 The Conversion Cycle 347

faulty cost system. Bill asked the team, ‘‘Is ACC begin- ‘‘Since ACC began accepting small-volume orders,

ning to show signs of a faulty cost system?’’ we have had our hands full. Each time we design a

Next, the team looked at the manufacturing overhead new part, a new program must be written. Addition-

breakdown (Case 6, Fig. 1). The current cost accounting ally, it seems the new small-volume parts we are pro-

system allocated 100 percent of this overhead to product

ducing are much more complex than the large-

based on labor dollars. The team felt ACC could do a

volume parts we produced just a few years ago. This

better job of tracing costs to products based on transac-

translates into more moves per run. Consequently,

tion volume. Jim explains:

we wind up performing AGV maintenance much

‘‘The manufacturing overhead really consists of more frequently. Sometimes I wish we would get rid

the six cost pools shown in Figure 1. Each of these of those AGVs; our old system of forklifts and opera-

activity cost pools should be traced individually to tors was much less resistant to change.’’

products based on the proportion of transactions

Sara Nightingale, the most experienced jobsetter at

they consume, not the amount of direct labor they

ACC, spoke about the current status of setups:

consume.’’

‘‘The changeover crew has changed drastically

The team conducted the following interviews to

recently. Our team has shifted from mostly

determine the specific transactions ACC should use to

mechanically skilled maintenance people to a

trace costs from activities to products.

team of highly trained programmers and mechani-

John ‘‘Bull’’ Adams, the supervisor in charge of ma-

terial movement, provided the floor layout shown in cally skilled people. This shift has greatly reduced

Figure 2 for Case 6 and commented on his department’s our head count. Yet the majority of our work is

workload: still spent on setup labor time.’’

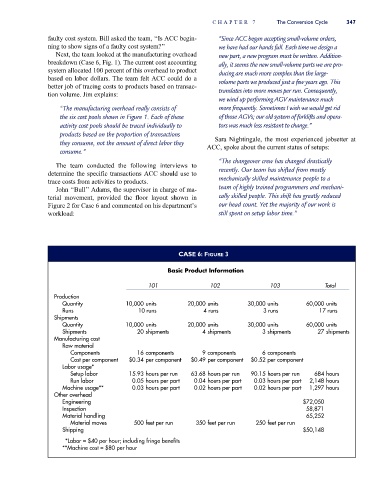

CASE 6: FIGURE 3

Basic Product Information

101 102 103 Total

Production

Quantity 10,000 units 20,000 units 30,000 units 60,000 units

Runs 10 runs 4 runs 3 runs 17 runs

Shipments

Quantity 10,000 units 20,000 units 30,000 units 60,000 units

Shipments 20 shipments 4 shipments 3 shipments 27 shipments

Manufacturing cost

Raw material

Components 16 components 9 components 6 components

Cost per component $0.34 per component $0.49 per component $0.52 per component

Labor usage*

Setup labor 15.93 hours per run 63.68 hours per run 90.15 hours per run 684 hours

Run labor 0.05 hours per part 0.04 hours per part 0.03 hours per part 2,148 hours

Machine usage** 0.03 hours per part 0.02 hours per part 0.02 hours per part 1,297 hours

Other overhead

Engineering $72,050

Inspection 58,871

Material handling 65,252

Material moves 500 feet per run 350 feet per run 250 feet per run

Shipping $50,148

*Labor = $40 per hour; including fringe benefits

**Machine cost = $80 per hour