Page 155 - Advanced Mine Ventilation

P. 155

Generation of Respirable Coal Dust 135

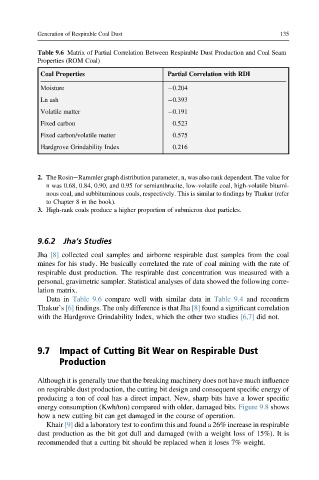

Table 9.6 Matrix of Partial Correlation Between Respirable Dust Production and Coal Seam

Properties (ROM Coal)

Coal Properties Partial Correlation with RDI

Moisture 0.204

Ln ash 0.393

Volatile matter 0.191

Fixed carbon 0.523

Fixed carbon/volatile matter 0.575

Hardgrove Grindability Index 0.216

2. The RosineRammler graph distribution parameter, n, was also rank dependent. The value for

n was 0.68, 0.84, 0.90, and 0.95 for semianthracite, low-volatile coal, high-volatile bitumi-

nous coal, and subbituminous coals, respectively. This is similar to findings by Thakur (refer

to Chapter 8 in the book).

3. High-rank coals produce a higher proportion of submicron dust particles.

9.6.2 Jha’s Studies

Jha [8] collected coal samples and airborne respirable dust samples from the coal

mines for his study. He basically correlated the rate of coal mining with the rate of

respirable dust production. The respirable dust concentration was measured with a

personal, gravimetric sampler. Statistical analyses of data showed the following corre-

lation matrix.

Data in Table 9.6 compare well with similar data in Table 9.4 and reconfirm

Thakur’s [6] findings. The only difference is that Jha [8] found a significant correlation

with the Hardgrove Grindability Index, which the other two studies [6,7] did not.

9.7 Impact of Cutting Bit Wear on Respirable Dust

Production

Although it is generally true that the breaking machinery does not have much influence

on respirable dust production, the cutting bit design and consequent specific energy of

producing a ton of coal has a direct impact. New, sharp bits have a lower specific

energy consumption (Kwh/ton) compared with older, damaged bits. Figure 9.8 shows

how a new cutting bit can get damaged in the course of operation.

Khair [9] did a laboratory test to confirm this and found a 26% increase in respirable

dust production as the bit got dull and damaged (with a weight loss of 15%). It is

recommended that a cutting bit should be replaced when it loses 7% weight.