Page 282 - Advanced Mine Ventilation

P. 282

Premining Degasification of Coal Seams 259

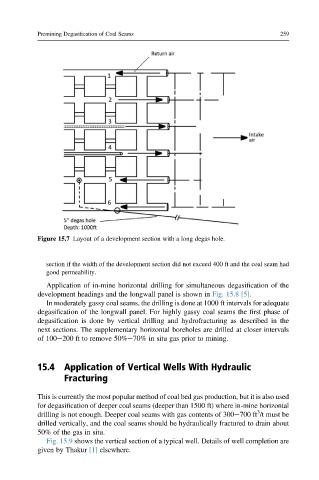

Figure 15.7 Layout of a development section with a long degas hole.

section if the width of the development section did not exceed 400 ft and the coal seam had

good permeability.

Application of in-mine horizontal drilling for simultaneous degasification of the

development headings and the longwall panel is shown in Fig. 15.8 [5].

In moderately gassy coal seams, the drilling is done at 1000 ft intervals for adequate

degasification of the longwall panel. For highly gassy coal seams the first phase of

degasification is done by vertical drilling and hydrofracturing as described in the

next sections. The supplementary horizontal boreholes are drilled at closer intervals

of 100e200 ft to remove 50%e70% in situ gas prior to mining.

15.4 Application of Vertical Wells With Hydraulic

Fracturing

This is currently the most popular method of coal bed gas production, but it is also used

for degasification of deeper coal seams (deeper than 1500 ft) where in-mine horizontal

3

drilling is not enough. Deeper coal seams with gas contents of 300e700 ft /t must be

drilled vertically, and the coal seams should be hydraulically fractured to drain about

50% of the gas in situ.

Fig. 15.9 shows the vertical section of a typical well. Details of well completion are

given by Thakur [1] elsewhere.