Page 284 - Advanced Mine Ventilation

P. 284

Premining Degasification of Coal Seams 261

In summary, a mixture of sand and water is pumped into the coal formation at

30 bbl/min or a higher rate (1 bbl ¼ 42 gallons). It creates a vertical fracture in coal

1

3

seams that is 1000 to 2000 ft long, / 2 to / 4 in. wide, and about 20 ft high at the

well bore. The width and height reduces to almost nil at the tip of the fracture at

1000 ft or so. Drilling is usually done three to 5 years ahead of mining to achieve

50% drainage of in situ gases.

A typical longwall face 1000 15,000 in area may need 10 to 12 vertical frac

0

0

wells for adequate degasification. When the reservoir pressure is reduced to less

than 200 psi, supplementary degasification is done with horizontal drilling to remove

additional 25%e30% of in situ gas content. Hydrofracking is typically done with plain

water or nitrogen foam, but gelled water and cross-linked gels have been also used

depending on the specifics of the coal seam. Refer to Chapter 4, Figure 4.7 for the layout

of frac wells on a typical longwall face. Average spacing is at 20e25 acres per well.

15.5 Application of Horizontal Boreholes Drilled From

Surface

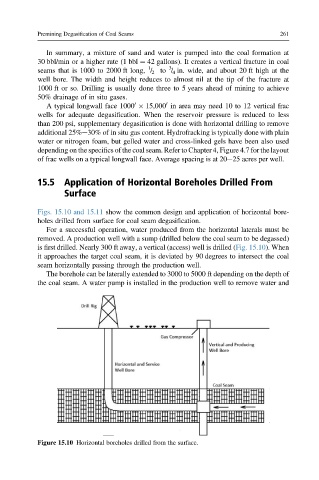

Figs. 15.10 and 15.11 show the common design and application of horizontal bore-

holes drilled from surface for coal seam degasification.

For a successful operation, water produced from the horizontal laterals must be

removed. A production well with a sump (drilled below the coal seam to be degassed)

is first drilled. Nearly 300 ft away, a vertical (access) well is drilled (Fig. 15.10). When

it approaches the target coal seam, it is deviated by 90 degrees to intersect the coal

seam horizontally passing through the production well.

The borehole can be laterally extended to 3000 to 5000 ft depending on the depth of

the coal seam. A water pump is installed in the production well to remove water and

Figure 15.10 Horizontal boreholes drilled from the surface.