Page 285 - Advanced Mine Ventilation

P. 285

262 Advanced Mine Ventilation

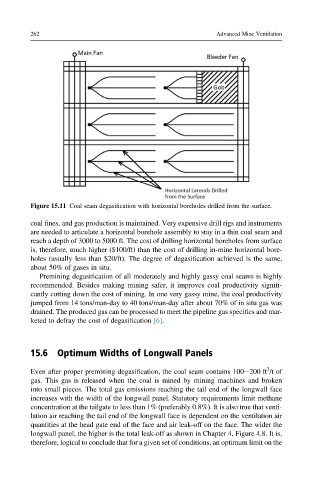

Figure 15.11 Coal seam degasification with horizontal boreholes drilled from the surface.

coal fines, and gas production is maintained. Very expensive drill rigs and instruments

are needed to articulate a horizontal borehole assembly to stay in a thin coal seam and

reach a depth of 3000 to 5000 ft. The cost of drilling horizontal boreholes from surface

is, therefore, much higher ($100/ft) than the cost of drilling in-mine horizontal bore-

holes (usually less than $20/ft). The degree of degasification achieved is the same,

about 50% of gases in situ.

Premining degasification of all moderately and highly gassy coal seams is highly

recommended. Besides making mining safer, it improves coal productivity signifi-

cantly cutting down the cost of mining. In one very gassy mine, the coal productivity

jumped from 14 tons/man-day to 40 tons/man-day after about 70% of in situ gas was

drained. The produced gas can be processed to meet the pipeline gas specifics and mar-

keted to defray the cost of degasification [6].

15.6 Optimum Widths of Longwall Panels

3

Even after proper premining degasification, the coal seam contains 100e200 ft /t of

gas. This gas is released when the coal is mined by mining machines and broken

into small pieces. The total gas emissions reaching the tail end of the longwall face

increases with the width of the longwall panel. Statutory requirements limit methane

concentration at the tailgate to less than 1% (preferably 0.8%). It is also true that venti-

lation air reaching the tail end of the longwall face is dependent on the ventilation air

quantities at the head gate end of the face and air leak-off on the face. The wider the

longwall panel, the higher is the total leak-off as shown in Chapter 4, Figure 4.8. It is,

therefore, logical to conclude that for a given set of conditions, an optimum limit on the