Page 375 - Advanced Mine Ventilation

P. 375

346 Advanced Mine Ventilation

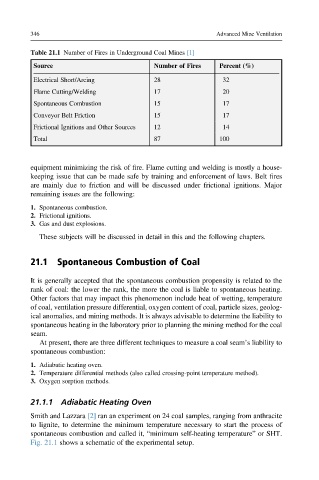

Table 21.1 Number of Fires in Underground Coal Mines [1]

Source Number of Fires Percent (%)

Electrical Short/Arcing 28 32

Flame Cutting/Welding 17 20

Spontaneous Combustion 15 17

Conveyor Belt Friction 15 17

Frictional Ignitions and Other Sources 12 14

Total 87 100

equipment minimizing the risk of fire. Flame cutting and welding is mostly a house-

keeping issue that can be made safe by training and enforcement of laws. Belt fires

are mainly due to friction and will be discussed under frictional ignitions. Major

remaining issues are the following:

1. Spontaneous combustion.

2. Frictional ignitions.

3. Gas and dust explosions.

These subjects will be discussed in detail in this and the following chapters.

21.1 Spontaneous Combustion of Coal

It is generally accepted that the spontaneous combustion propensity is related to the

rank of coal: the lower the rank, the more the coal is liable to spontaneous heating.

Other factors that may impact this phenomenon include heat of wetting, temperature

of coal, ventilation pressure differential, oxygen content of coal, particle sizes, geolog-

ical anomalies, and mining methods. It is always advisable to determine the liability to

spontaneous heating in the laboratory prior to planning the mining method for the coal

seam.

At present, there are three different techniques to measure a coal seam’s liability to

spontaneous combustion:

1. Adiabatic heating oven.

2. Temperature differential methods (also called crossing-point temperature method).

3. Oxygen sorption methods.

21.1.1 Adiabatic Heating Oven

Smith and Lazzara [2] ran an experiment on 24 coal samples, ranging from anthracite

to lignite, to determine the minimum temperature necessary to start the process of

spontaneous combustion and called it, “minimum self-heating temperature” or SHT.

Fig. 21.1 shows a schematic of the experimental setup.