Page 396 - Advanced Mine Ventilation

P. 396

Prevention of Frictional Ignitions 365

Machine design parameters that influence frictional ignitions include (1) optimiza-

tion of cutting speed, (2) optimum depth of cut, and (3) bit designs incorporating

polycrystalline diamonds for both drilling roof bolt holes and coal cutting.

22.1 Coal Seam Degasification

This subject has been discussed in detail in Chapters 15, 16, and 17. In summary, coal

3

seams containing more than 100 ft /t of gas can be broadly classified as (1) moderately

3

3

gassy (gas contents, 100e300 ft /t) or (2) highly gassy (gas contents 300e700 ft /t)

coal seams. Moderately gassy coal seams should be degassed before mining to reduce

3

their gas content to less than 100 ft /t. Such seams are generally less than 1500 ft in

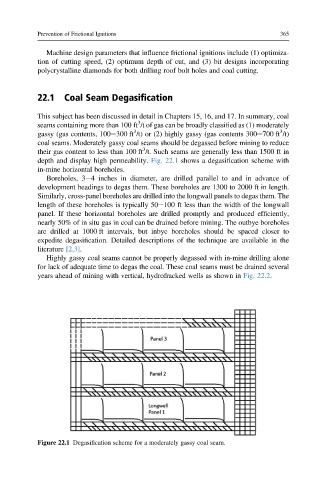

depth and display high permeability. Fig. 22.1 shows a degasification scheme with

in-mine horizontal boreholes.

Boreholes, 3e4 inches in diameter, are drilled parallel to and in advance of

development headings to degas them. These boreholes are 1300 to 2000 ft in length.

Similarly, cross-panel boreholes are drilled into the longwall panels to degas them. The

length of these boreholes is typically 50e100 ft less than the width of the longwall

panel. If these horizontal boreholes are drilled promptly and produced efficiently,

nearly 50% of in situ gas in coal can be drained before mining. The outbye boreholes

are drilled at 1000 ft intervals, but inbye boreholes should be spaced closer to

expedite degasification. Detailed descriptions of the technique are available in the

literature [2,3].

Highly gassy coal seams cannot be properly degassed with in-mine drilling alone

for lack of adequate time to degas the coal. These coal seams must be drained several

years ahead of mining with vertical, hydrofracked wells as shown in Fig. 22.2.

Figure 22.1 Degasification scheme for a moderately gassy coal seam.