Page 400 - Advanced Mine Ventilation

P. 400

Prevention of Frictional Ignitions 369

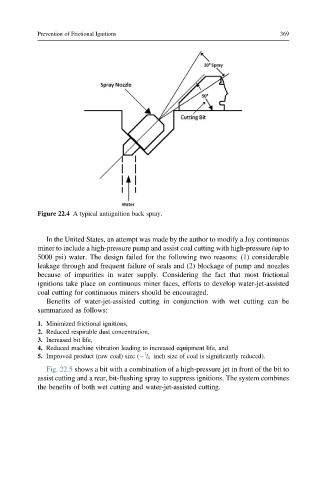

Figure 22.4 A typical antiignition back spray.

In the United States, an attempt was made by the author to modify a Joy continuous

miner to include a high-pressure pump and assist coal cutting with high-pressure (up to

5000 psi) water. The design failed for the following two reasons: (1) considerable

leakage through and frequent failure of seals and (2) blockage of pump and nozzles

because of impurities in water supply. Considering the fact that most frictional

ignitions take place on continuous miner faces, efforts to develop water-jet-assisted

coal cutting for continuous miners should be encouraged.

Benefits of water-jet-assisted cutting in conjunction with wet cutting can be

summarized as follows:

1. Minimized frictional ignitions,

2. Reduced respirable dust concentration,

3. Increased bit life,

4. Reduced machine vibration leading to increased equipment life, and

1

5. Improved product (raw coal) size ( / 4 inch size of coal is significantly reduced).

Fig. 22.5 shows a bit with a combination of a high-pressure jet in front of the bit to

assist cutting and a rear, bit-flushing spray to suppress ignitions. The system combines

the benefits of both wet cutting and water-jet-assisted cutting.