Page 404 - Advanced Mine Ventilation

P. 404

Prevention of Frictional Ignitions 373

3. Incorporating wet cutting on all mining machines and eventually design machines that assist

coal cutting with high pressure water.

4. Using larger cutting tools made of high-grade stainless steel to provide deep cutting without

frequent breakdowns.

5. Using high attack angle bits, such as radial or forward attack bits. The machine should be

originally designed to incorporate these bits. A retrofit is generally unsuccessful.

6. Bit tip material made of polycrystalline diamonds, which can be directly deposited on

tungsten carbide or bonded to it as a thin wafer.

The suggested steps will not only make mining safer but also more economic by

enhancing coal productivity and creating a source of extra revenue from coalbed

methane. Loss of production due to mandatory suspension of mining subsequent to

an ignition will also be minimized.

22.6 Frictional Ignitions Caused by Belt Conveyors

Belt conveyors are quickly replacing all old methods of coal transport. As mentioned

in Chapter 21, they create nearly 17% of mine fires but they are usually contained

quickly. An exception is the Wilberg Mine Fire [11], where 27 lives were lost due

to a belt fire.

Francart [12] reports an average of 5.7 incidents of belt fire per 1000 mines over the

period 1980 to 2005. A breakdown of belt conveyor ignition sources is shown in

Table 22.2.

Belt friction accounts for nearly 50 percent of all belt fires.

The belt drives and conveyor transfer points are the first primary ignition source for

many reasons. Electrical sources are likely to exist near the drives. Spillage of coal at

such location is also very likely. Belt slippage can cause the belt fabric to heat up and

ignite itself or the spilled coal underneath.

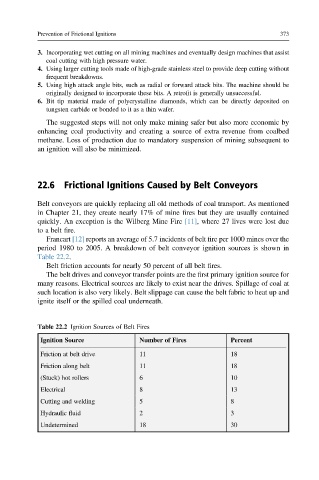

Table 22.2 Ignition Sources of Belt Fires

Ignition Source Number of Fires Percent

Friction at belt drive 11 18

Friction along belt 11 18

(Stuck) hot rollers 6 10

Electrical 8 13

Cutting and welding 5 8

Hydraulic fluid 2 3

Undetermined 18 30