Page 402 - Advanced Mine Ventilation

P. 402

Prevention of Frictional Ignitions 371

Figure 22.6 Geometry of a conical bit for cutting coal.

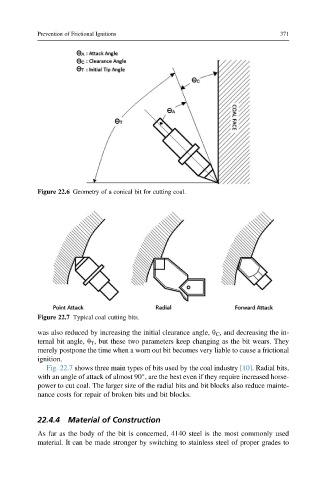

Figure 22.7 Typical coal cutting bits.

was also reduced by increasing the initial clearance angle, q C , and decreasing the in-

ternal bit angle, q T , but these two parameters keep changing as the bit wears. They

merely postpone the time when a worn out bit becomes very liable to cause a frictional

ignition.

Fig. 22.7 shows three main types of bits used by the coal industry [10]. Radial bits,

with an angle of attack of almost 90 , are the best even if they require increased horse-

power to cut coal. The larger size of the radial bits and bit blocks also reduce mainte-

nance costs for repair of broken bits and bit blocks.

22.4.4 Material of Construction

As far as the body of the bit is concerned, 4140 steel is the most commonly used

material. It can be made stronger by switching to stainless steel of proper grades to