Page 127 - Advances In Productive, Safe, and Responsible Coal Mining

P. 127

Developing effective proximity detection systems for underground coal mines 111

evaluate the performance of PDS. Performance was evaluated primarily by determining

the distance from the MWC to the CMM when warning and stop zones were detected.

The goal of these tests was to assess the performance of the second generation of

proximity detection systems in terms of functionality and repeatability. These tests

followed a protocol developed with input from industry and the West Virginia Mine

Safety Technology Task Force. NIOSH researchers used a custom measurement appa-

ratus to characterize the warning zone and stop zone distances by moving an MWC

toward the machine until an MWC alarm was activated. Researchers recorded the dis-

tance at which the alarm was activated for the warning zone, continued to move

toward the machine until an alarm was activated for the stop zone, then recorded that

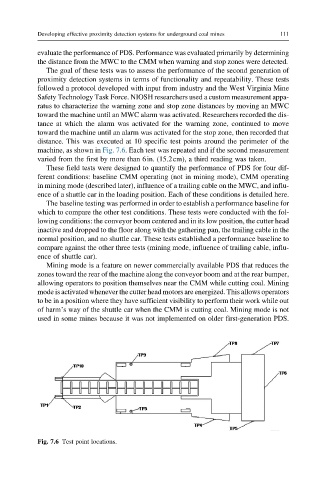

distance. This was executed at 10 specific test points around the perimeter of the

machine, as shown in Fig. 7.6. Each test was repeated and if the second measurement

varied from the first by more than 6in. (15.2cm), a third reading was taken.

These field tests were designed to quantify the performance of PDS for four dif-

ferent conditions: baseline CMM operating (not in mining mode), CMM operating

in mining mode (described later), influence of a trailing cable on the MWC, and influ-

ence of a shuttle car in the loading position. Each of these conditions is detailed here.

The baseline testing was performed in order to establish a performance baseline for

which to compare the other test conditions. These tests were conducted with the fol-

lowing conditions: the conveyor boom centered and in its low position, the cutter head

inactive and dropped to the floor along with the gathering pan, the trailing cable in the

normal position, and no shuttle car. These tests established a performance baseline to

compare against the other three tests (mining mode, influence of trailing cable, influ-

ence of shuttle car).

Mining mode is a feature on newer commercially available PDS that reduces the

zones toward the rear of the machine along the conveyor boom and at the rear bumper,

allowing operators to position themselves near the CMM while cutting coal. Mining

mode is activated whenever the cutter head motors are energized. This allows operators

to be in a position where they have sufficient visibility to perform their work while out

of harm’s way of the shuttle car when the CMM is cutting coal. Mining mode is not

used in some mines because it was not implemented on older first-generation PDS.

Fig. 7.6 Test point locations.