Page 188 - Advances In Productive, Safe, and Responsible Coal Mining

P. 188

Out-of-seam dilution: Economic impacts and control strategies 167

Table 9.4 Incremental cost impacts of OSD in 2010 US$/ton [2, 12, 13]

Roof Floor Total OSD cost

dilution dilution (clean ton basis)

Base mining cost $4.69 $4.69 $1.55

Materials handling $0.75 $0.75 $0.25

Base processing $1.40 $1.40 $0.46

cost

Rotary breaker $0.15 – $0.03

Maintenance $0.30 – $0.06

Viscosity effect – $0.21 $0.03

Flocculant usage – $0.43 $0.05

Quality impact $5.09 $1.26 $1.22

cost

Waste disposal $1.13 $0.54 $0.30

cost

Total $13.51 $9.28 $3.95

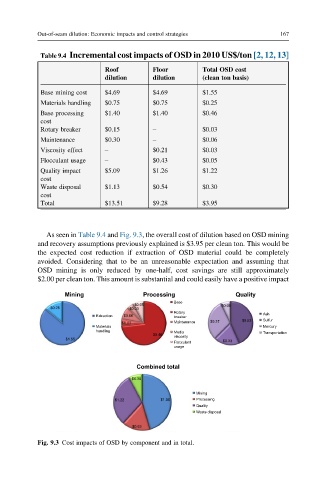

As seen in Table 9.4 and Fig. 9.3, the overall cost of dilution based on OSD mining

and recovery assumptions previously explained is $3.95 per clean ton. This would be

the expected cost reduction if extraction of OSD material could be completely

avoided. Considering that to be an unreasonable expectation and assuming that

OSD mining is only reduced by one-half, cost savings are still approximately

$2.00 per clean ton. This amount is substantial and could easily have a positive impact

Mining Processing Quality

Base

$0.05 $0.09

$0.25 $0.03

Rotary Ash

Extraction $0.06 breaker

$0.03 Maintenance $0.37 $0.53 Sulfur

Materials Mercury

handling Media Transportation

$0.46 viscosity

$1.55 $0.23

Flocculant

usage

Combined total

$0.30

Mining

$1.22 $1.80 Processing

Quality

Waste disposal

$0.63

Fig. 9.3 Cost impacts of OSD by component and in total.