Page 190 - Advances In Productive, Safe, and Responsible Coal Mining

P. 190

Out-of-seam dilution: Economic impacts and control strategies 169

best addressed through workforce education and awareness programs. OSD that

results from engineered systems is best addressed with more advanced engineering.

9.4.1 Workforce education and awareness

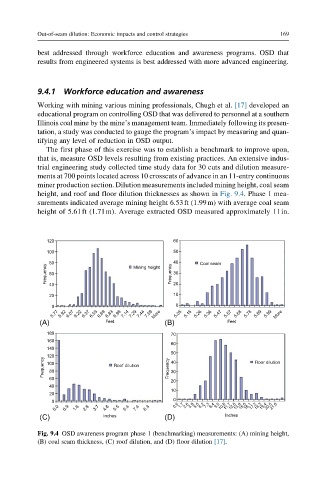

Working with mining various mining professionals, Chugh et al. [17] developed an

educational program on controlling OSD that was delivered to personnel at a southern

Illinois coal mine by the mine’s management team. Immediately following its presen-

tation, a study was conducted to gauge the program’s impact by measuring and quan-

tifying any level of reduction in OSD output.

The first phase of this exercise was to establish a benchmark to improve upon,

that is, measure OSD levels resulting from existing practices. An extensive indus-

trial engineering study collected time study data for 30 cuts and dilution measure-

ments at 700 points located across 10 crosscuts of advance in an 11-entry continuous

miner production section. Dilution measurements included mining height, coal seam

height, and roof and floor dilution thicknesses as shown in Fig. 9.4. Phase 1 mea-

surements indicated average mining height 6.53ft (1.99m) with average coal seam

height of 5.61ft (1.71m). Average extracted OSD measured approximately 11in.

120 60

100 50

40

Frequency 80 Mining height Frequency 30 Coal seam

60

20

40

20 10

0 0

5.77 5.92 6.07 6.22 6.37 6.53 6.68 6.83 6.98 7.14 7.29 7.44 7.59 More 5.05 5.15 5.26 5.36 5.47 5.57 5.68 5.78 5.89 5.99 More

(A) Feet (B) Feet

180 70

160

60

140

50

Frequency 120 Roof dilution Frequency 40 Floor dilution

100

80

30

60

20

40

10

20

0

0

0.0 0.9 1.8 2.8 3.7 4.6 5.5 6.4 7.4 8.3 0.6 1.7 2.8 3.9 5.0 6.2 7.3 8.4 9.5 10.6 11.7 12.8 13.9 15.0 16.1 17.2 18.3 19.4 20.5 21.6

(C) Inches (D) Inches

Fig. 9.4 OSD awareness program phase 1 (benchmarking) measurements: (A) mining height,

(B) coal seam thickness, (C) roof dilution, and (D) floor dilution [17].