Page 241 - Advances In Productive, Safe, and Responsible Coal Mining

P. 241

220 Advances in Productive, Safe, and Responsible Coal Mining

12.4 Case studies

In this section, three case studies are presented describing the development of noise

controls for underground coal mining equipment.

12.4.1 Noise controls for longwall-cutting drums

Longwall systems are sets of machines that work in full synchrony to extract ore from

underground mines. Although there are two basic types of longwall systems—

shearers and ploughs—in the United States (US), approximately 98% of longwall

mines use shearers. These systems are mainly used in coal, but also a few trona mines.

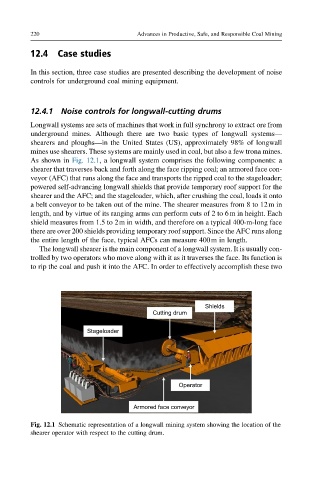

As shown in Fig. 12.1, a longwall system comprises the following components: a

shearer that traverses back and forth along the face ripping coal; an armored face con-

veyor (AFC) that runs along the face and transports the ripped coal to the stageloader;

powered self-advancing longwall shields that provide temporary roof support for the

shearer and the AFC; and the stageloader, which, after crushing the coal, loads it onto

a belt conveyor to be taken out of the mine. The shearer measures from 8 to 12m in

length, and by virtue of its ranging arms can perform cuts of 2 to 6m in height. Each

shield measures from 1.5 to 2m in width, and therefore on a typical 400-m-long face

there are over 200 shields providing temporary roof support. Since the AFC runs along

the entire length of the face, typical AFCs can measure 400m in length.

The longwall shearer is the main component of a longwall system. It is usually con-

trolled by two operators who move along with it as it traverses the face. Its function is

to rip the coal and push it into the AFC. In order to effectively accomplish these two

Shields

Cutting drum

Stageloader

Operator

Armored face conveyor

Fig. 12.1 Schematic representation of a longwall mining system showing the location of the

shearer operator with respect to the cutting drum.