Page 89 - Advances In Productive, Safe, and Responsible Coal Mining

P. 89

74 Advances in Productive, Safe, and Responsible Coal Mining

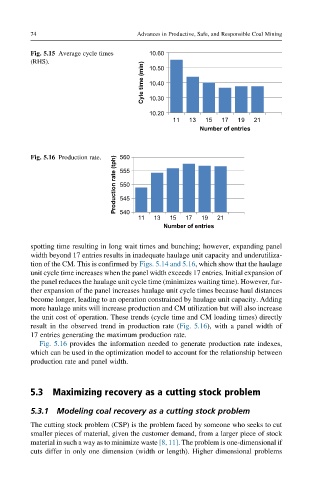

Fig. 5.15 Average cycle times 10.60

(RHS). 10.50

Cyle time (min) 10.40

10.30

10.20

11 13 15 17 19 21

Number of entries

Fig. 5.16 Production rate. 560

Production rate (tph) 550

555

545

540

11 13 15 17 19 21

Number of entries

spotting time resulting in long wait times and bunching; however, expanding panel

width beyond 17 entries results in inadequate haulage unit capacity and underutiliza-

tion of the CM. This is confirmed by Figs. 5.14 and 5.16, which show that the haulage

unit cycle time increases when the panel width exceeds 17 entries. Initial expansion of

the panel reduces the haulage unit cycle time (minimizes waiting time). However, fur-

ther expansion of the panel increases haulage unit cycle times because haul distances

become longer, leading to an operation constrained by haulage unit capacity. Adding

more haulage units will increase production and CM utilization but will also increase

the unit cost of operation. These trends (cycle time and CM loading times) directly

result in the observed trend in production rate (Fig. 5.16), with a panel width of

17 entries generating the maximum production rate.

Fig. 5.16 provides the information needed to generate production rate indexes,

which can be used in the optimization model to account for the relationship between

production rate and panel width.

5.3 Maximizing recovery as a cutting stock problem

5.3.1 Modeling coal recovery as a cutting stock problem

The cutting stock problem (CSP) is the problem faced by someone who seeks to cut

smaller pieces of material, given the customer demand, from a larger piece of stock

material in such a way as to minimize waste [8, 11]. The problem is one-dimensional if

cuts differ in only one dimension (width or length). Higher dimensional problems