Page 122 - Advances in bioenergy (2016)

P. 122

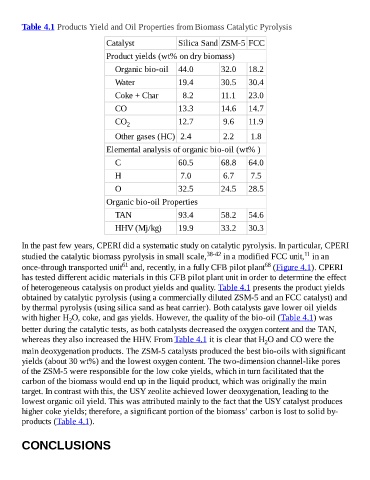

Table 4.1 Products Yield and Oil Properties from Biomass Catalytic Pyrolysis

Catalyst Silica Sand ZSM-5 FCC

Product yields (wt% on dry biomass)

Organic bio-oil 44.0 32.0 18.2

Water 19.4 30.5 30.4

Coke + Char 8.2 11.1 23.0

CO 13.3 14.6 14.7

CO 2 12.7 9.6 11.9

Other gases (HC) 2.4 2.2 1.8

Elemental analysis of organic bio-oil (wt% )

C 60.5 68.8 64.0

H 7.0 6.7 7.5

O 32.5 24.5 28.5

Organic bio-oil Properties

TAN 93.4 58.2 54.6

HHV (Mj/kg) 19.9 33.2 30.3

In the past few years, CPERI did a systematic study on catalytic pyrolysis. In particular, CPERI

11

studied the catalytic biomass pyrolysis in small scale, 38-42 in a modified FCC unit, in an

61

68

once-through transported unit and, recently, in a fully CFB pilot plant (Figure 4.1). CPERI

has tested different acidic materials in this CFB pilot plant unit in order to determine the effect

of heterogeneous catalysis on product yields and quality. Table 4.1 presents the product yields

obtained by catalytic pyrolysis (using a commercially diluted ZSM-5 and an FCC catalyst) and

by thermal pyrolysis (using silica sand as heat carrier). Both catalysts gave lower oil yields

with higher H O, coke, and gas yields. However, the quality of the bio-oil (Table 4.1) was

2

better during the catalytic tests, as both catalysts decreased the oxygen content and the TAN,

whereas they also increased the HHV. From Table 4.1 it is clear that H O and CO were the

2

main deoxygenation products. The ZSM-5 catalysts produced the best bio-oils with significant

yields (about 30 wt%) and the lowest oxygen content. The two-dimension channel-like pores

of the ZSM-5 were responsible for the low coke yields, which in turn facilitated that the

carbon of the biomass would end up in the liquid product, which was originally the main

target. In contrast with this, the USY zeolite achieved lower deoxygenation, leading to the

lowest organic oil yield. This was attributed mainly to the fact that the USY catalyst produces

higher coke yields; therefore, a significant portion of the biomass’ carbon is lost to solid by-

products (Table 4.1).

CONCLUSIONS