Page 147 - Advances in bioenergy (2016)

P. 147

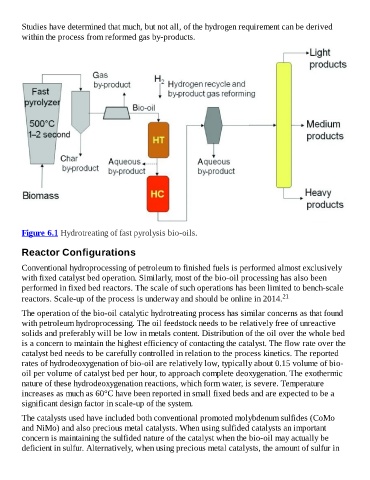

Studies have determined that much, but not all, of the hydrogen requirement can be derived

within the process from reformed gas by-products.

Figure 6.1 Hydrotreating of fast pyrolysis bio-oils.

Reactor Configurations

Conventional hydroprocessing of petroleum to finished fuels is performed almost exclusively

with fixed catalyst bed operation. Similarly, most of the bio-oil processing has also been

performed in fixed bed reactors. The scale of such operations has been limited to bench-scale

reactors. Scale-up of the process is underway and should be online in 2014. 21

The operation of the bio-oil catalytic hydrotreating process has similar concerns as that found

with petroleum hydroprocessing. The oil feedstock needs to be relatively free of unreactive

solids and preferably will be low in metals content. Distribution of the oil over the whole bed

is a concern to maintain the highest efficiency of contacting the catalyst. The flow rate over the

catalyst bed needs to be carefully controlled in relation to the process kinetics. The reported

rates of hydrodeoxygenation of bio-oil are relatively low, typically about 0.15 volume of bio-

oil per volume of catalyst bed per hour, to approach complete deoxygenation. The exothermic

nature of these hydrodeoxygenation reactions, which form water, is severe. Temperature

increases as much as 60°C have been reported in small fixed beds and are expected to be a

significant design factor in scale-up of the system.

The catalysts used have included both conventional promoted molybdenum sulfides (CoMo

and NiMo) and also precious metal catalysts. When using sulfided catalysts an important

concern is maintaining the sulfided nature of the catalyst when the bio-oil may actually be

deficient in sulfur. Alternatively, when using precious metal catalysts, the amount of sulfur in