Page 176 - Advances in bioenergy (2016)

P. 176

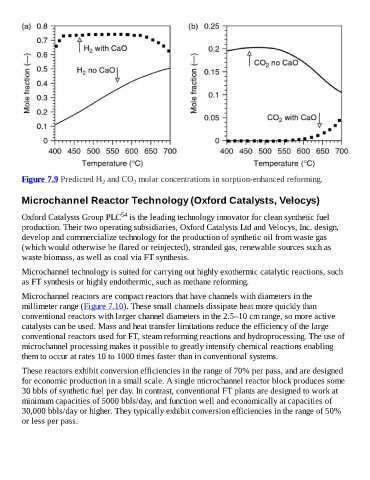

Figure 7.9 Predicted H and CO molar concentrations in sorption-enhanced reforming.

2

2

Microchannel Reactor Technology (Oxford Catalysts, Velocys)

54

Oxford Catalysts Group PLC is the leading technology innovator for clean synthetic fuel

production. Their two operating subsidiaries, Oxford Catalysts Ltd and Velocys, Inc. design,

develop and commercialize technology for the production of synthetic oil from waste gas

(which would otherwise be flared or reinjected), stranded gas, renewable sources such as

waste biomass, as well as coal via FT synthesis.

Microchannel technology is suited for carrying out highly exothermic catalytic reactions, such

as FT synthesis or highly endothermic, such as methane reforming.

Microchannel reactors are compact reactors that have channels with diameters in the

millimeter range (Figure 7.10). These small channels dissipate heat more quickly than

conventional reactors with larger channel diameters in the 2.5–10 cm range, so more active

catalysts can be used. Mass and heat transfer limitations reduce the efficiency of the large

conventional reactors used for FT, steam reforming reactions and hydroprocessing. The use of

microchannel processing makes it possible to greatly intensify chemical reactions enabling

them to occur at rates 10 to 1000 times faster than in conventional systems.

These reactors exhibit conversion efficiencies in the range of 70% per pass, and are designed

for economic production in a small scale. A single microchannel reactor block produces some

30 bbls of synthetic fuel per day. In contrast, conventional FT plants are designed to work at

minimum capacities of 5000 bbls/day, and function well and economically at capacities of

30,000 bbls/day or higher. They typically exhibit conversion efficiencies in the range of 50%

or less per pass.