Page 232 - Advances in Eco-Fuels for a Sustainable Environment

P. 232

196 Advances in Eco-Fuels for a Sustainable Environment

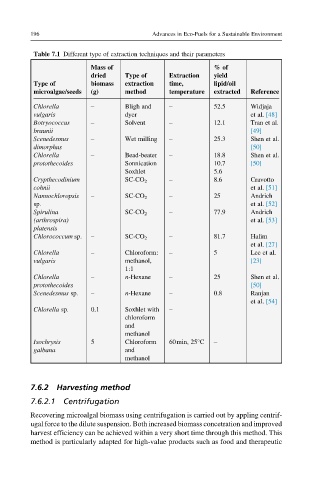

Table 7.1 Different type of extraction techniques and their parameters

Mass of %of

dried Type of Extraction yield

Type of biomass extraction time, lipid/oil

microalgae/seeds (g) method temperature extracted Reference

Chlorella – Bligh and – 52.5 Widjaja

vulgaris dyer et al. [48]

Botryococcus – Solvent – 12.1 Tran et al.

braunii [49]

Scenedesmus – Wet milling – 25.3 Shen et al.

dimorphus [50]

Chlorella – Bead-beater – 18.8 Shen et al.

protothecoides Sonnication 10.7 [50]

Soxhlet 5.6

Crypthecodinium – SC-CO 2 – 8.6 Cravotto

cohnii et al. [51]

Nannochloropsis – SC-CO 2 – 25 Andrich

sp. et al. [52]

Spirulina – SC-CO 2 – 77.9 Andrich

(arthrospira) et al. [53]

platensis

Chlorococcum sp. – SC-CO 2 – 81.7 Halim

et al. [27]

Chlorella – Chloroform: – 5 Lee et al.

vulgaris methanol, [23]

1:1

Chlorella – n-Hexane – 25 Shen et al.

protothecoides [50]

Scenedesmus sp. – n-Hexane – 0.8 Ranjan

et al. [54]

Chlorella sp. 0.1 Soxhlet with –

chloroform

and

methanol

Isochrysis 5 Chloroform 60min, 25°C –

galbana and

methanol

7.6.2 Harvesting method

7.6.2.1 Centrifugation

Recovering microalgal biomass using centrifugation is carried out by appling centrif-

ugal force to the dilute suspension. Both increased biomass concetration and improved

harvest efficiency can be achieved within a very short time through this method. This

method is particularly adapted for high-value products such as food and therapeutic