Page 468 - Advances in Eco-Fuels for a Sustainable Environment

P. 468

Eco friendly biofuels for CI engine applications 421

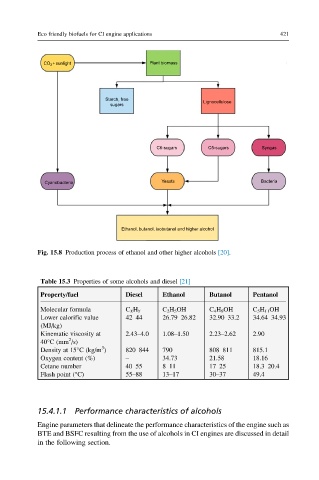

CO 2 + sunlight Plant biomass

Starch, free Lignocellulose

sugars

C6-sugars C5-sugars Syngas

Cyanobacteria Yeasts Bacteria

Ethanol, butanol, isobutanol and higher alcohol

Fig. 15.8 Production process of ethanol and other higher alcohols [20].

Table 15.3 Properties of some alcohols and diesel [21]

Property/fuel Diesel Ethanol Butanol Pentanol

Molecular formula C X H Y C 2 H 5 OH C 4 H 9 OH C 5 H 11 OH

Lower calorific value 42–44 26.79–26.82 32.90–33.2 34.64–34.93

(MJ/kg)

Kinematic viscosity at 2.43–4.0 1.08–1.50 2.23–2.62 2.90

2

40°C (mm /s)

3

Density at 15°C (kg/m ) 820–844 790 808–811 815.1

Oxygen content (%) – 34.73 21.58 18.16

Cetane number 40–55 8–11 17–25 18.3–20.4

Flash point (°C) 55–88 13–17 30–37 49.4

15.4.1.1 Performance characteristics of alcohols

Engine parameters that delineate the performance characteristics of the engine such as

BTE and BSFC resulting from the use of alcohols in CI engines are discussed in detail

in the following section.