Page 54 - Advances in Eco-Fuels for a Sustainable Environment

P. 54

Ecofuel feedstocks and their prospects 31

Table 2.9 Characteristics of some digestible feedstocks for biogas generation

Type of feedstock Organic content C/N ratio

Animal slurry Carbohydrates, proteins, lipids 3–20

Straw Carbohydrates, lipids 80–100

Grass – 12–25

Grass silage – 10–25

Flotation sludge 65%–70% proteins –

– 30%–35% lipids –

2.4.2 Bioethanol production

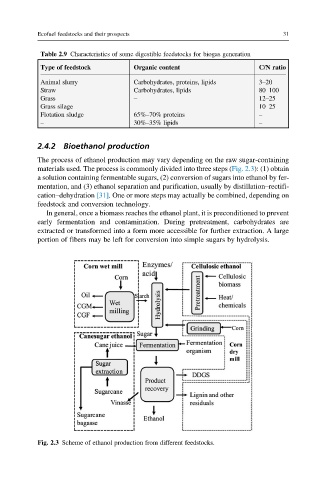

The process of ethanol production may vary depending on the raw sugar-containing

materials used. The process is commonly divided into three steps (Fig. 2.3): (1) obtain

a solution containing fermentable sugars, (2) conversion of sugars into ethanol by fer-

mentation, and (3) ethanol separation and purification, usually by distillation–rectifi-

cation–dehydration [31]. One or more steps may actually be combined, depending on

feedstock and conversion technology.

In general, once a biomass reaches the ethanol plant, it is preconditioned to prevent

early fermentation and contamination. During pretreatment, carbohydrates are

extracted or transformed into a form more accessible for further extraction. A large

portion of fibers may be left for conversion into simple sugars by hydrolysis.

Fig. 2.3 Scheme of ethanol production from different feedstocks.