Page 55 - Advances in Eco-Fuels for a Sustainable Environment

P. 55

32 Advances in Eco-Fuels for a Sustainable Environment

Recirculation or immobilization of yeasts increases cell density in the fermenter,

improving their activity and increasing process productivity. Temperatures between

25°Cand30°Cfor6–72harerequiredforfermentation,dependingonhydrolysatecom-

position, cell density, and yeast species. The “broth” typically contains 8%–14% eth-

anol on a volume basis, and the distillation step yields an azeotropic (constant boiling

point) mixture made up of 95.5% alcohol and 4.5% water. This is the “hydrous” or

“hydrated” ethanol that is, subsequently dehydrated to obtain an “anhydrous” ethanol

containing up to 99.6% alcohol and 0.4% water. The remaining volume from the dis-

tillation process (vinasse, or stillage) can be volatilized to make coproducts, including

steam and electricity, animal feed products, fertilizers, or other valuable products [34].

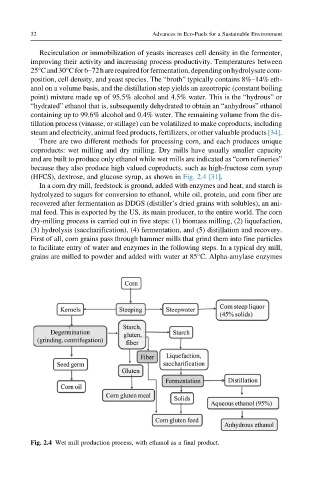

There are two different methods for processing corn, and each produces unique

coproducts: wet milling and dry milling. Dry mills have usually smaller capacity

and are built to produce only ethanol while wet mills are indicated as “corn refineries”

because they also produce high valued coproducts, such as high-fructose corn syrup

(HFCS), dextrose, and glucose syrup, as shown in Fig. 2.4 [31].

In a corn dry mill, feedstock is ground, added with enzymes and heat, and starch is

hydrolyzed to sugars for conversion to ethanol, while oil, protein, and corn fiber are

recovered after fermentation as DDGS (distiller’s dried grains with solubles), an ani-

mal feed. This is exported by the US, its main producer, to the entire world. The corn

dry-milling process is carried out in five steps: (1) biomass milling, (2) liquefaction,

(3) hydrolysis (saccharification), (4) fermentation, and (5) distillation and recovery.

First of all, corn grains pass through hammer mills that grind them into fine particles

to facilitate entry of water and enzymes in the following steps. In a typical dry mill,

grains are milled to powder and added with water at 85°C. Alpha-amylase enzymes

Fig. 2.4 Wet mill production process, with ethanol as a final product.