Page 60 - Advances in Eco-Fuels for a Sustainable Environment

P. 60

Ecofuel feedstocks and their prospects 37

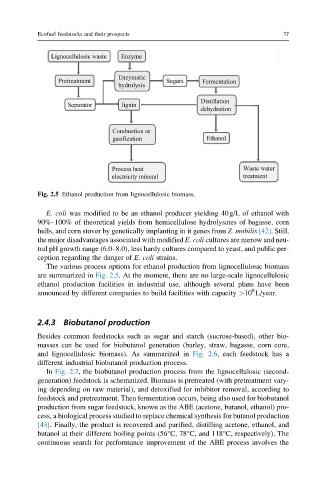

Fig. 2.5 Ethanol production from lignocellulosic biomass.

E. coli was modified to be an ethanol producer yielding 40g/L of ethanol with

90%–100% of theoretical yields from hemicellulose hydrolysates of bagasse, corn

hulls, and corn stover by genetically implanting in it genes from Z. mobilis [42]. Still,

the major disadvantages associated with modified E. coli cultures are narrow and neu-

tral pH growth range (6.0–8.0), less hardy cultures compared to yeast, and public per-

ception regarding the danger of E. coli strains.

The various process options for ethanol production from lignocellulosic biomass

are summarized in Fig. 2.5. At the moment, there are no large-scale lignocellulosic

ethanol production facilities in industrial use, although several plans have been

8

announced by different companies to build facilities with capacity >10 L/year.

2.4.3 Biobutanol production

Besides common feedstocks such as sugar and starch (sucrose-based), other bio-

masses can be used for biobutanol generation (barley, straw, bagasse, corn core,

and lignocellulosic biomass). As summarized in Fig. 2.6, each feedstock has a

different industrial biobutanol production process.

In Fig. 2.7, the biobutanol production process from the lignocellulosic (second-

generation) feedstock is schematized. Biomass is pretreated (with pretreatment vary-

ing depending on raw material), and detoxified for inhibitor removal, according to

feedstock and pretreatment. Then fermentation occurs, being also used for biobutanol

production from sugar feedstock, known as the ABE (acetone, butanol, ethanol) pro-

cess, a biological process studied to replace chemical synthesis for butanol production

[43]. Finally, the product is recovered and purified, distilling acetone, ethanol, and

butanol at their different boiling points (56°C, 78°C, and 118°C, respectively). The

continuous search for performance improvement of the ABE process involves the