Page 61 - Advances in Eco-Fuels for a Sustainable Environment

P. 61

38 Advances in Eco-Fuels for a Sustainable Environment

Sucrose

Starchy

containing materials Lignocellulosic Microalgae

biomass

feedstocks

Pretreatment

Fermentation Hydrolysis Gasification

(one-stage)

Catalyzed

Fermentation Fermentation

reaction

First-generation Second-generation Third-generation

biobutanol biobutanol biobutanol

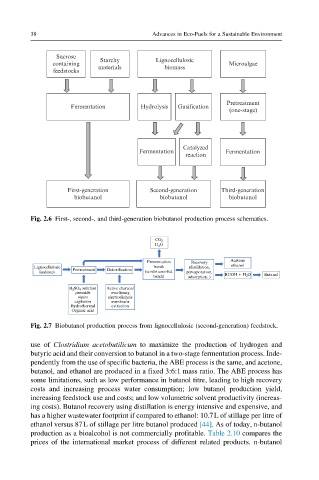

Fig. 2.6 First-, second-, and third-generation biobutanol production process schematics.

CO 2

H 2 O

Fermentation Recovery Acetone

Lignocellulosic Pretreatment Detoxification batch (distillation, ethanol

feedstock (continuous-fed pervaporation, BUOH + H 2 O

batch) adsorption..) Butanol

H 2 SO 4 solution Active charcoal

peroxide overliming

steam electrodialysis

explosion membrane

Hydrothermal extraction

Organic acid

Fig. 2.7 Biobutanol production process from lignocellulosic (second-generation) feedstock.

use of Clostridium acetobutilicum to maximize the production of hydrogen and

butyric acid and their conversion to butanol in a two-stage fermentation process. Inde-

pendently from the use of specific bacteria, the ABE process is the same, and acetone,

butanol, and ethanol are produced in a fixed 3:6:1 mass ratio. The ABE process has

some limitations, such as low performance in butanol titre, leading to high recovery

costs and increasing process water consumption; low butanol production yield,

increasing feedstock use and costs; and low volumetric solvent productivity (increas-

ing costs). Butanol recovery using distillation is energy intensive and expensive, and

has a higher wastewater footprint if compared to ethanol: 10.7L of stillage per litre of

ethanol versus 87L of stillage per litre butanol produced [44]. As of today, n-butanol

production as a bioalcohol is not commercially profitable. Table 2.10 compares the

prices of the international market process of different related products. n-butanol