Page 152 - Advances in Textile Biotechnology

P. 152

Enzymatic versus chemical processing of cotton 133

In this chapter the processes of conventional chemical preparation,

including desizing, scouring and bleaching, are compared with those of fully

enzymatic processes that, to date, include desizing and scouring but not

bleaching. There have been research efforts regarding the latter, but no

effective industrial methods. The processes will be evaluated with regard to

effectiveness on cotton properties, their environmental and energy impacts,

and their costs and benefi ts.

6.2 Chemistry and structure of the cotton fi ber

Cotton is by far the most important natural textile fiber in use. Most accounts

put the worldwide usage of cotton at about forty percent of all fi ber con-

sumed for textile purposes (Fiber Organon, 2005). Cotton comes from

plants of the genus Gossypium, with only 4 of the 33 species being of major

commercial importance (Chaudry and Guitchounts, 2003). For most of the

world, G. hirsutum (American Upland) and G. barbadense (Egyptian, and

other extra-long staple varieties) are the major cotton fi bers. Two other

coarse short staple cottons, G. herbaceum and G. arboretum, are grown in

southeast Asia.

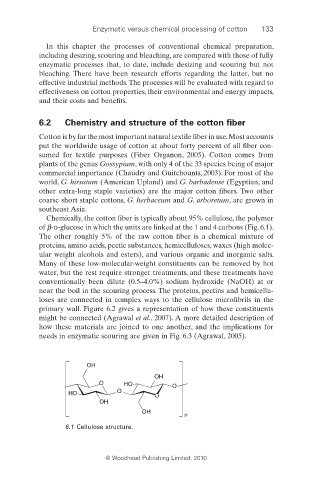

Chemically, the cotton fiber is typically about 95% cellulose, the polymer

of β-d-glucose in which the units are linked at the 1 and 4 carbons (Fig. 6.1).

The other roughly 5% of the raw cotton fiber is a chemical mixture of

proteins, amino acids, pectic substances, hemicelluloses, waxes (high molec-

ular weight alcohols and esters), and various organic and inorganic salts.

Many of these low-molecular-weight constituents can be removed by hot

water, but the rest require stronger treatments, and these treatments have

conventionally been dilute (0.5–4.0%) sodium hydroxide (NaOH) at or

near the boil in the scouring process. The proteins, pectins and hemicellu-

loses are connected in complex ways to the cellulose microfibrils in the

primary wall. Figure 6.2 gives a representation of how these constituents

might be connected (Agrawal et al., 2007). A more detailed description of

how these materials are joined to one another, and the implications for

needs in enzymatic scouring are given in Fig. 6.3 (Agrawal, 2005).

OH

OH

O HO O

HO O O

OH

OH

n

6.1 Cellulose structure.

© Woodhead Publishing Limited, 2010